Sanyo M9802 - why is this happening to my cassettes?

- Thread starter dan

- Start date

thinkchronicity

Member (SA)

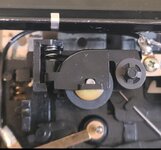

There's no adjustment for it. The pinch roller assembly is on a plastic post held in by a circular clip with 4 fingers. Happened with the old roller as well after I took it off to clean it with rubber renue.Not seen that before. Is the new roller parallel to the capstan?

thinkchronicity

Member (SA)

But is it parallel?

It needs to be. If it's badly off you might get these results.

It needs to be. If it's badly off you might get these results.

I'm almost wondering if it's the spring that puts pressure on the pinch roller. I did kinda screw it up when it fell on the floor and I accidentally ran it over with my wheelchair. I straightened it out as much as possible.But is it parallel?

It needs to be. If it's badly off you might get these results.

Attachments

thinkchronicity

Member (SA)

I can't access the service manual. Don't know if you can put up a good pic of the pinch roller assembly? So the old roller was only mangling the tape after you ran over the spring?

Mention of the 'plastic post' leads me to think that may have warped or something.

Mention of the 'plastic post' leads me to think that may have warped or something.

I can't access the service manual. Don't know if you can put up a good pic of the pinch roller assembly? So the old roller was only mangling the tape after you ran over the spring?

Mention of the 'plastic post' leads me to think that may have warped or something.

Attachments

BoomboxLover48

Boomus Fidelis

Looks like the pinch roller axle, or the pinch roller hole size is not the correct.

Is the axle of the pinch roller firm on the spring-loaded assembly?

Here the axle looks like a plastic pin. A steel axle is always preferred.

Normally it is a steel pin axle one has to push through the holder and the pinch roller. This pin will only go from one side and for removing it needs to be pushed out from the other side. The steel pin barely slides through the pinch roller hole and is lubricated. There is not much clearance at all except for an oil film.

Normally the hole on the pinch roller is 2.0 mm diameter in most cases and 2.5mm in some other cases. So, the center pin axle diameter should match the pinch roller middle hole size.

You changed the pinch roller (13mm x 8.3mm x 2.5mm). What was the center pin diameter?

If the hole diameter on the pinch roller is 2.0 mm it needs a 2.0 mm diameter axle. The axle should fit well on the bracket.

If not, the pinch roller will not ride well on the capstan. This uneven ride is pinching the tape and squeezing it away from its normal path.

Is the axle of the pinch roller firm on the spring-loaded assembly?

Here the axle looks like a plastic pin. A steel axle is always preferred.

Normally it is a steel pin axle one has to push through the holder and the pinch roller. This pin will only go from one side and for removing it needs to be pushed out from the other side. The steel pin barely slides through the pinch roller hole and is lubricated. There is not much clearance at all except for an oil film.

Normally the hole on the pinch roller is 2.0 mm diameter in most cases and 2.5mm in some other cases. So, the center pin axle diameter should match the pinch roller middle hole size.

You changed the pinch roller (13mm x 8.3mm x 2.5mm). What was the center pin diameter?

If the hole diameter on the pinch roller is 2.0 mm it needs a 2.0 mm diameter axle. The axle should fit well on the bracket.

If not, the pinch roller will not ride well on the capstan. This uneven ride is pinching the tape and squeezing it away from its normal path.

Last edited:

The pinch roller axle is the original metal one, 2.5mm. The pinch roller, old and new measure exactly the same, Other than the old pinch roller is worn down to about 12.8mm. There is a 13 stamped in the plastic of the old roller. Can a dab of clock movement oil be used on the pinch roller axle?Looks like the pinch roller axle, or the pinch roller hole size is not the correct.

Is the axle of the pinch roller firm on the spring-loaded assembly?

Here the axle looks like a plastic pin. A steel axle is always preferred.

Normally it is a steel pin axle one has to push through the holder and the pinch roller. This pin will only go from one side and for removing it needs to be pushed out from the other side. The steel pin barely slides through the pinch roller hole and is lubricated. There is not much clearance at all except for an oil film.

Normally the hole on the pinch roller is 2.0 mm diameter in most cases and 2.5mm in some other cases. So, the center pin axle diameter should match the pinch roller middle hole size.

You changed the pinch roller (13mm x 8.3mm x 2.5mm). What was the center pin diameter?

If the hole diameter on the pinch roller is 2.0 mm it needs a 2.0 mm diameter axle. The axle should fit well on the bracket.

If not, the pinch roller will not ride well on the capstan. This uneven ride is pinching the tape and squeezing it away from its normal path.

I think this may be an issue with the spring. Tomorrow afternoon I will take it apart again and see what's going on.

The spring is 0.37mm wire, an outside diameter of 3.92mm and I'm guess a length of 11mm but the length was measured after I damaged it and tried to fix it. The spring looks to have 6 turns.

Anywhere I can source this exact spring?

Attachments

BoomboxLover48

Boomus Fidelis

You can use a little 3 in 1 oil on the axle taking care not to get on the rubber of the pinch roller.

ACE Hardware is a place where we can find many types of springs.

Exact springs are hard to find. Make sure the spring is not all the way compressed when the pinch roller is pressed on the capstan.

It doesn't need a lot of pressure.

Without a tape, in play mode do you see the pinch roller moving well?

In play mode the pinch roller makes only a slight contact with the capstan just enough to pull the tape to the take up reel.

ACE Hardware is a place where we can find many types of springs.

Exact springs are hard to find. Make sure the spring is not all the way compressed when the pinch roller is pressed on the capstan.

It doesn't need a lot of pressure.

Without a tape, in play mode do you see the pinch roller moving well?

In play mode the pinch roller makes only a slight contact with the capstan just enough to pull the tape to the take up reel.

Last edited:

thinkchronicity

Member (SA)

Looking at your clear pics again, it does appear that spring applies pressure on one side mainly....which is an odd design. So, as said above, too much pressure = bad.

I ended up buying some springs on Amazon. 0.4mm x 4mm × 10mm. But instead of 6 turns, they have 8. Because the old spring was damaged and deformed, I think it was applying pressure on an angle. I also reverted to the old pinch roller just incase the new one was imperfect somehow. I can play cassettes ok now, except for the ones that wrapped around the spool previously, because the tape is already crinkled, it wants to still wrap around the spool when starting the tape from the beginning. Mind you, those same damaged tapes don't experience this phenomenon on my jvc. They spool fine.

Another issue I have is the autostop was barely working with the new pinch roller, a hit and miss, with the old one, it doesn't work at all. There seems to be enough pressure from the pinch roller on the capstan. If I press the play button down while playing at end of tape, it will engage the autostop mechanism.

The lesson here is don't mess with the pinch roller and assembly unless it's eating your tape. I was trying to hunt down some wobble in the pitch when end up being caused by using a belt too tight. The motor has some rubber isolation/ shock absorber where the shaft is mounted and if your belt is too tight, the shaft gets pulled to one side, the rubber shock absorber can't do it's thing and your hear slight wobble in pitch. Same goes for belt size. An sbo 10.0 belt on this model will introduce pitch wobble while the correct sbs 10.0 belt won't. Make sure you're belts are perfect before doing anything else. If it ain't broke, don't fix.

Another issue I have is the autostop was barely working with the new pinch roller, a hit and miss, with the old one, it doesn't work at all. There seems to be enough pressure from the pinch roller on the capstan. If I press the play button down while playing at end of tape, it will engage the autostop mechanism.

The lesson here is don't mess with the pinch roller and assembly unless it's eating your tape. I was trying to hunt down some wobble in the pitch when end up being caused by using a belt too tight. The motor has some rubber isolation/ shock absorber where the shaft is mounted and if your belt is too tight, the shaft gets pulled to one side, the rubber shock absorber can't do it's thing and your hear slight wobble in pitch. Same goes for belt size. An sbo 10.0 belt on this model will introduce pitch wobble while the correct sbs 10.0 belt won't. Make sure you're belts are perfect before doing anything else. If it ain't broke, don't fix.

Attachments

I seem to have fixed the spool issue and autostop not working issue.

First, I took out the pinch roller wheel, washed it with dawn, scrubbed it with the soap and some bounty paper towel. Got off any residue from rubber renue and later cleanings with isopropyl alcohol. Also cleaned the capstan. I air dried the roller with compressed air duster as to not contaminate it with lint. Also handled the roller with vinyl gloves during the install as to not get skin oils on it.

Then, I took out that 10mm pinch roller spring, put it on a shaft of a screwdriver and stretched it out with my fingers to a length of 12mm.

This made things better for the autostop, but not 100% for all tapes and not consistent. The capstan spun, but not the pinch roller. I noticed that if I pushed the tape upwards from the bottom, the autostop would engage because there was enough pressure to get the pinch roller rolling.

There is a metal clip on the cassette player that holds the bottom of the tape. I bent the metal clip upward, just enough that it applies some upwards pressure to the tape and this got the autostop to work 100% of the time.

Also noticed after this, the tape was spooling correctly, even the previously damaged tapes that had crinkled tape and would spool incorrectly.

I think the fix is a combination of all the things I did above. Hopefully, the fix lasts.

First, I took out the pinch roller wheel, washed it with dawn, scrubbed it with the soap and some bounty paper towel. Got off any residue from rubber renue and later cleanings with isopropyl alcohol. Also cleaned the capstan. I air dried the roller with compressed air duster as to not contaminate it with lint. Also handled the roller with vinyl gloves during the install as to not get skin oils on it.

Then, I took out that 10mm pinch roller spring, put it on a shaft of a screwdriver and stretched it out with my fingers to a length of 12mm.

This made things better for the autostop, but not 100% for all tapes and not consistent. The capstan spun, but not the pinch roller. I noticed that if I pushed the tape upwards from the bottom, the autostop would engage because there was enough pressure to get the pinch roller rolling.

There is a metal clip on the cassette player that holds the bottom of the tape. I bent the metal clip upward, just enough that it applies some upwards pressure to the tape and this got the autostop to work 100% of the time.

Also noticed after this, the tape was spooling correctly, even the previously damaged tapes that had crinkled tape and would spool incorrectly.

I think the fix is a combination of all the things I did above. Hopefully, the fix lasts.

Attachments

Transistorized

Member (SA)

I discovered a long time ago how a pinch roller can affect a cassette player. Just like belts, you have the normal size issues but then you have the type of compound of the rubber itself. My Sony TC-k850es is very very picky. If you don't have exactly the right roller, tension, alignment and torque spot on, it will turn your tapes into dental floss. Some rollers are soft and grippy, some a little harder and some decks need a pinch roller that is every so slightly convex. This is to ensure that the tape stays centered on the roller. It is so slight that most of the time, the only way to get a visual is to clean with IPA and watch how the roller dries. A good pinch roller will dry in the middle first and then spread to the outside area.

A cassette wanting to be eaten after the leader is a roller/torque and possible alignment issue. If there isn't an adjustment, it could also be a worn capstan bearing causing the tape to skew to one side or the other. Which brings me to another technical thing that some deck manufactures do when its needed. They will burnish the capstan. On certain decks that do this, they start eating tapes when the capstan becomes polished over the years of playing. Not all decks do this, but the ones that are like this, act up when the capstan becomes too smooth.

A cassette wanting to be eaten after the leader is a roller/torque and possible alignment issue. If there isn't an adjustment, it could also be a worn capstan bearing causing the tape to skew to one side or the other. Which brings me to another technical thing that some deck manufactures do when its needed. They will burnish the capstan. On certain decks that do this, they start eating tapes when the capstan becomes polished over the years of playing. Not all decks do this, but the ones that are like this, act up when the capstan becomes too smooth.