Sanyo M9802 - why is this happening to my cassettes?

- Thread starter dan

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

thinkchronicity

Member (SA)

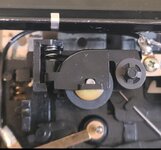

There's no adjustment for it. The pinch roller assembly is on a plastic post held in by a circular clip with 4 fingers. Happened with the old roller as well after I took it off to clean it with rubber renue.Not seen that before. Is the new roller parallel to the capstan?

thinkchronicity

Member (SA)

But is it parallel?

It needs to be. If it's badly off you might get these results.

It needs to be. If it's badly off you might get these results.

I'm almost wondering if it's the spring that puts pressure on the pinch roller. I did kinda screw it up when it fell on the floor and I accidentally ran it over with my wheelchair. I straightened it out as much as possible.But is it parallel?

It needs to be. If it's badly off you might get these results.

Attachments

thinkchronicity

Member (SA)

I can't access the service manual. Don't know if you can put up a good pic of the pinch roller assembly? So the old roller was only mangling the tape after you ran over the spring?

Mention of the 'plastic post' leads me to think that may have warped or something.

Mention of the 'plastic post' leads me to think that may have warped or something.

I can't access the service manual. Don't know if you can put up a good pic of the pinch roller assembly? So the old roller was only mangling the tape after you ran over the spring?

Mention of the 'plastic post' leads me to think that may have warped or something.

Attachments

BoomboxLover48

Boomus Fidelis

Looks like the pinch roller axle, or the pinch roller hole size is not the correct.

Is the axle of the pinch roller firm on the spring-loaded assembly?

Here the axle looks like a plastic pin. A steel axle is always preferred.

Normally it is a steel pin axle one has to push through the holder and the pinch roller. This pin will only go from one side and for removing it needs to be pushed out from the other side. The steel pin barely slides through the pinch roller hole and is lubricated. There is not much clearance at all except for an oil film.

Normally the hole on the pinch roller is 2.0 mm diameter in most cases and 2.5mm in some other cases. So, the center pin axle diameter should match the pinch roller middle hole size.

You changed the pinch roller (13mm x 8.3mm x 2.5mm). What was the center pin diameter?

If the hole diameter on the pinch roller is 2.0 mm it needs a 2.0 mm diameter axle. The axle should fit well on the bracket.

If not, the pinch roller will not ride well on the capstan. This uneven ride is pinching the tape and squeezing it away from its normal path.

Is the axle of the pinch roller firm on the spring-loaded assembly?

Here the axle looks like a plastic pin. A steel axle is always preferred.

Normally it is a steel pin axle one has to push through the holder and the pinch roller. This pin will only go from one side and for removing it needs to be pushed out from the other side. The steel pin barely slides through the pinch roller hole and is lubricated. There is not much clearance at all except for an oil film.

Normally the hole on the pinch roller is 2.0 mm diameter in most cases and 2.5mm in some other cases. So, the center pin axle diameter should match the pinch roller middle hole size.

You changed the pinch roller (13mm x 8.3mm x 2.5mm). What was the center pin diameter?

If the hole diameter on the pinch roller is 2.0 mm it needs a 2.0 mm diameter axle. The axle should fit well on the bracket.

If not, the pinch roller will not ride well on the capstan. This uneven ride is pinching the tape and squeezing it away from its normal path.

Last edited:

The pinch roller axle is the original metal one, 2.5mm. The pinch roller, old and new measure exactly the same, Other than the old pinch roller is worn down to about 12.8mm. There is a 13 stamped in the plastic of the old roller. Can a dab of clock movement oil be used on the pinch roller axle?Looks like the pinch roller axle, or the pinch roller hole size is not the correct.

Is the axle of the pinch roller firm on the spring-loaded assembly?

Here the axle looks like a plastic pin. A steel axle is always preferred.

Normally it is a steel pin axle one has to push through the holder and the pinch roller. This pin will only go from one side and for removing it needs to be pushed out from the other side. The steel pin barely slides through the pinch roller hole and is lubricated. There is not much clearance at all except for an oil film.

Normally the hole on the pinch roller is 2.0 mm diameter in most cases and 2.5mm in some other cases. So, the center pin axle diameter should match the pinch roller middle hole size.

You changed the pinch roller (13mm x 8.3mm x 2.5mm). What was the center pin diameter?

If the hole diameter on the pinch roller is 2.0 mm it needs a 2.0 mm diameter axle. The axle should fit well on the bracket.

If not, the pinch roller will not ride well on the capstan. This uneven ride is pinching the tape and squeezing it away from its normal path.

I think this may be an issue with the spring. Tomorrow afternoon I will take it apart again and see what's going on.

The spring is 0.37mm wire, an outside diameter of 3.92mm and I'm guess a length of 11mm but the length was measured after I damaged it and tried to fix it. The spring looks to have 6 turns.

Anywhere I can source this exact spring?

Attachments

BoomboxLover48

Boomus Fidelis

You can use a little 3 in 1 oil on the axle taking care not to get on the rubber of the pinch roller.

ACE Hardware is a place where we can find many types of springs.

Exact springs are hard to find. Make sure the spring is not all the way compressed when the pinch roller is pressed on the capstan.

It doesn't need a lot of pressure.

Without a tape, in play mode do you see the pinch roller moving well?

In play mode the pinch roller makes only a slight contact with the capstan just enough to pull the tape to the take up reel.

ACE Hardware is a place where we can find many types of springs.

Exact springs are hard to find. Make sure the spring is not all the way compressed when the pinch roller is pressed on the capstan.

It doesn't need a lot of pressure.

Without a tape, in play mode do you see the pinch roller moving well?

In play mode the pinch roller makes only a slight contact with the capstan just enough to pull the tape to the take up reel.

Last edited:

thinkchronicity

Member (SA)

Looking at your clear pics again, it does appear that spring applies pressure on one side mainly....which is an odd design. So, as said above, too much pressure = bad.