JVC M90 screws and switch cap

- Thread starter blu_fuz

- Start date

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

caution

Member (SA)

Yes actually 1.65mm is VERY close to 0.065", which is 1.651 mm, or 15.38 threads/inch. No inch-based screw uses a fractional value for this.

But metric defines the actual thread pitch, so this screw would be M4x1.65. This makes more sense because I can buy M3.5x1.65 screws, but nothing in M4 Very odd screw.

Very odd screw.

I like that you also adjusted the thread shape to perform optimally in plastic

But metric defines the actual thread pitch, so this screw would be M4x1.65. This makes more sense because I can buy M3.5x1.65 screws, but nothing in M4

Very odd screw.

Very odd screw.I like that you also adjusted the thread shape to perform optimally in plastic

Trommelmops

Member (SA)

It exists screws for plastic in a special norm. There I have the shape from.

I have compared the exist scews with mine. The shape of the thread angles are defined.

And I have grind the lathe tool to these special angles.

my screws are better than the originals

but screws with m3 X 1,65 I have never seen and where have you see these screws? The problem with the screws is that they are not cutted they will be roll forged.

Oh m3,5 sorry but this is easy........

I can do this......

I have thread cutters here in m3,5

Stop!!!! M3,5 have definetly not this Pitch!!!

Where have you seen the screws with 1,65 Pitch??????????????

I have compared the exist scews with mine. The shape of the thread angles are defined.

And I have grind the lathe tool to these special angles.

my screws are better than the originals

but screws with m3 X 1,65 I have never seen and where have you see these screws? The problem with the screws is that they are not cutted they will be roll forged.

Oh m3,5 sorry but this is easy........

I can do this......

I have thread cutters here in m3,5

Stop!!!! M3,5 have definetly not this Pitch!!!

Where have you seen the screws with 1,65 Pitch??????????????

caution

Member (SA)

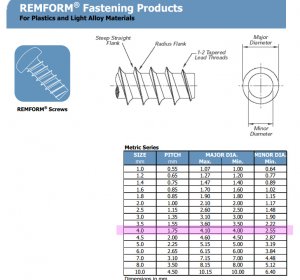

Plastite 45, Remform, Remform II and Remform II HS all have close versions, but nothing at m4x1.65.Trommelmops said:Where have you seen the screws with 1,65 Pitch??????????????

There's probably other companies that make these, but didn't look too hard....

Probably in Japan somewhere that I cannot search

Trommelmops

Member (SA)

Trommelmops

Member (SA)

Little update:

in the meantime i have try out to create a switchcap.....And let me say the following:

At this moment one of the testcaps is on the way to blue_fuz that he can tell me about the fitting and some other questions i will have........

that he can tell me about the fitting and some other questions i will have........

This is only for a test, i have one made in alu....should be a little surprise to him

I know i have told that this isnt possible, but i changed my own opinion: One smart guy sayed to me: Trommelmops what you not do you cannot learn

Oh he's so right......

Im sure you see the first testcap which isnt not yet finished to 100% on a picture soon.....

in the meantime i have try out to create a switchcap.....And let me say the following:

At this moment one of the testcaps is on the way to blue_fuz

that he can tell me about the fitting and some other questions i will have........

that he can tell me about the fitting and some other questions i will have........This is only for a test, i have one made in alu....should be a little surprise to him

I know i have told that this isnt possible, but i changed my own opinion: One smart guy sayed to me: Trommelmops what you not do you cannot learn

Oh he's so right......

Im sure you see the first testcap which isnt not yet finished to 100% on a picture soon.....

Trommelmops

Member (SA)

Looks good and when they have a little to much pitch I can do the correct pitch now

From now on I can make them in 1.65mm pitch and can change the lathe tool a little......

From now on I can make them in 1.65mm pitch and can change the lathe tool a little......

Trommelmops

Member (SA)

Not needed Joe I have all info's.....

More needed is the switch cap.....if it fits

Then I have the correct dimension and can make a final one

More needed is the switch cap.....if it fits

Then I have the correct dimension and can make a final one

Trommelmops

Member (SA)

OK...i need help to understand: Is the gap to tight? Which thickness has the slidermaterial?

I have made the testthing with 1.15mm gap but i think is 1.2mm?????

I need then a new measurement from you with the correct thickness......

Cool that the screws working

I have made the testthing with 1.15mm gap but i think is 1.2mm?????

I need then a new measurement from you with the correct thickness......

Cool that the screws working

Timecop1987

Member (SA)

Trommelmops - Is it possible to recreate some more M90-screws? Mine is missing 4 of these! Hit me up (I speak german aswell)

Trommelmops

Member (SA)

if anybody need some more or different screws or something else i can made......let me know

The Mops was very busy the last time

The Mops was very busy the last time

Trommelmops

Member (SA)

Im sorry Dave, my english is worst. Have problems to understand it.......Can you explain it for a foreigner pls a little easier

- Status

- Not open for further replies.