Radio raheem

Requiem Æternam

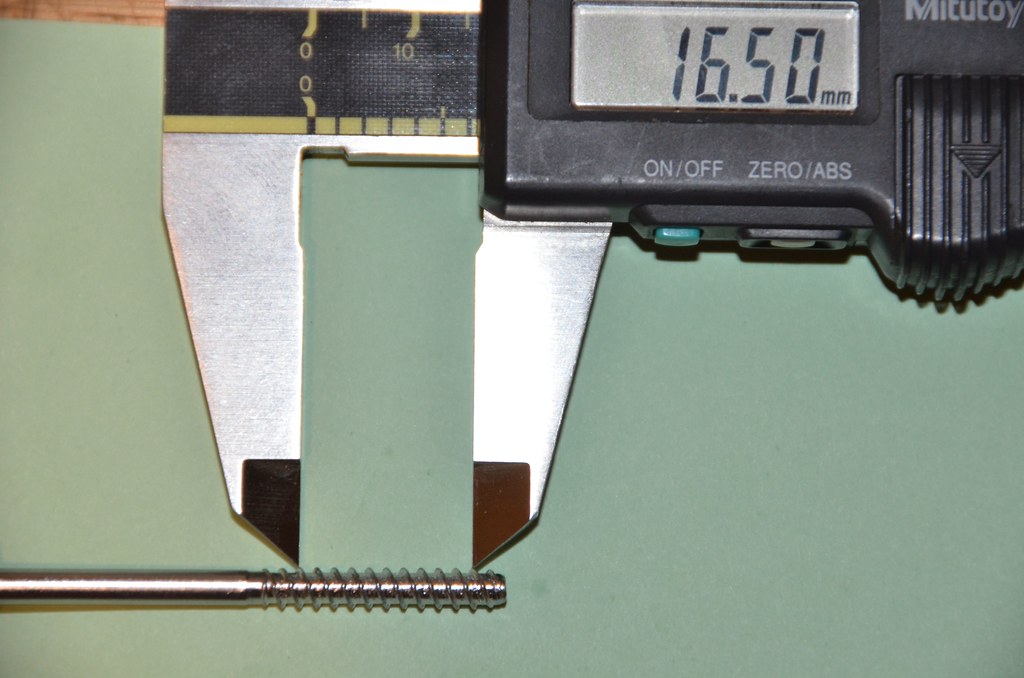

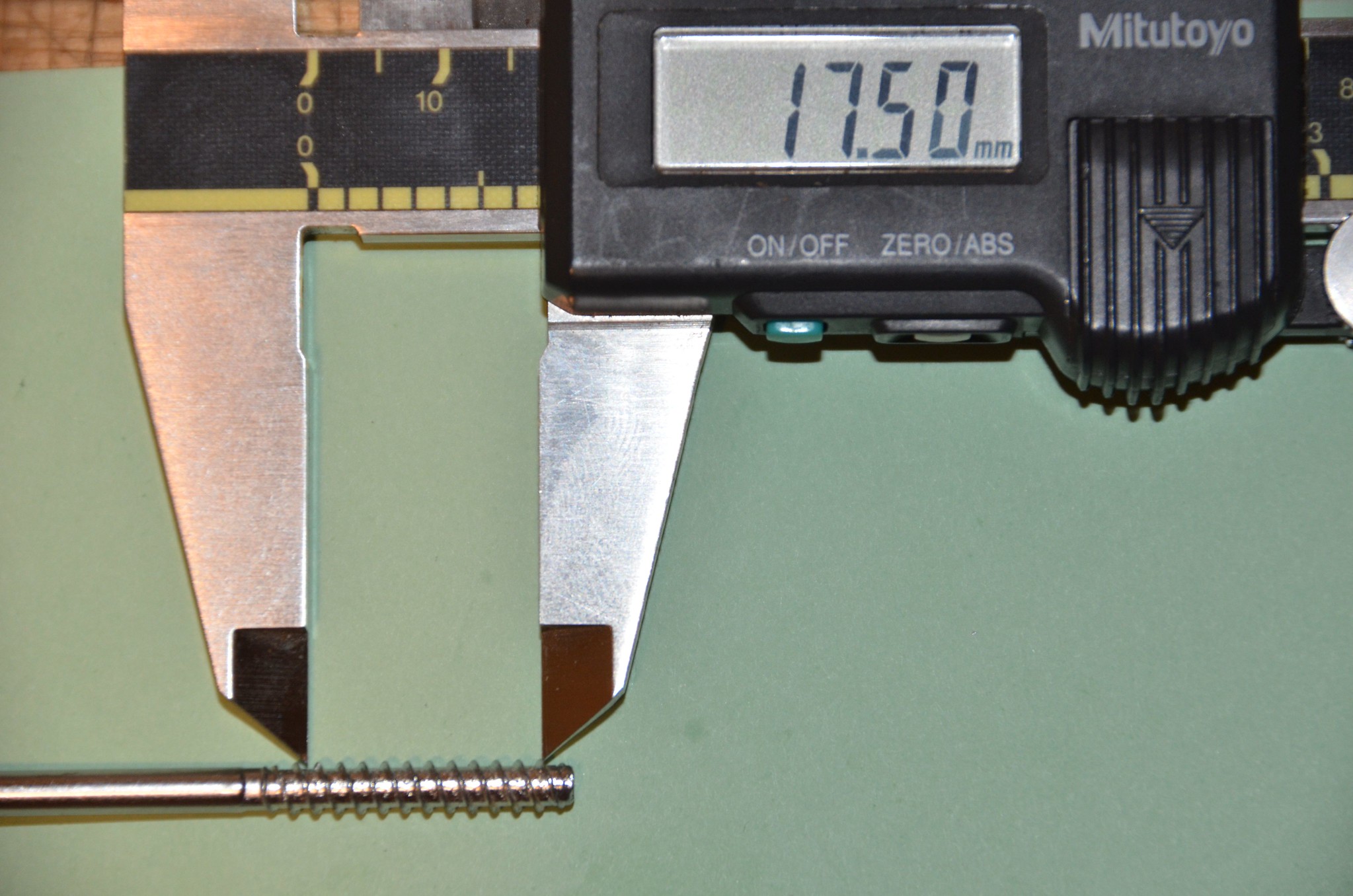

No worries Caution and yes you are correct Sir.....the only other screws that arn't original as you have confirmed is the small screw on the right out of the 4 screws ohh and the long screw on the left isn't original either....what one would give for a screw lolcaution said:T;hanks for catching that Rimmer, actually two of them are wrong. Should've known better

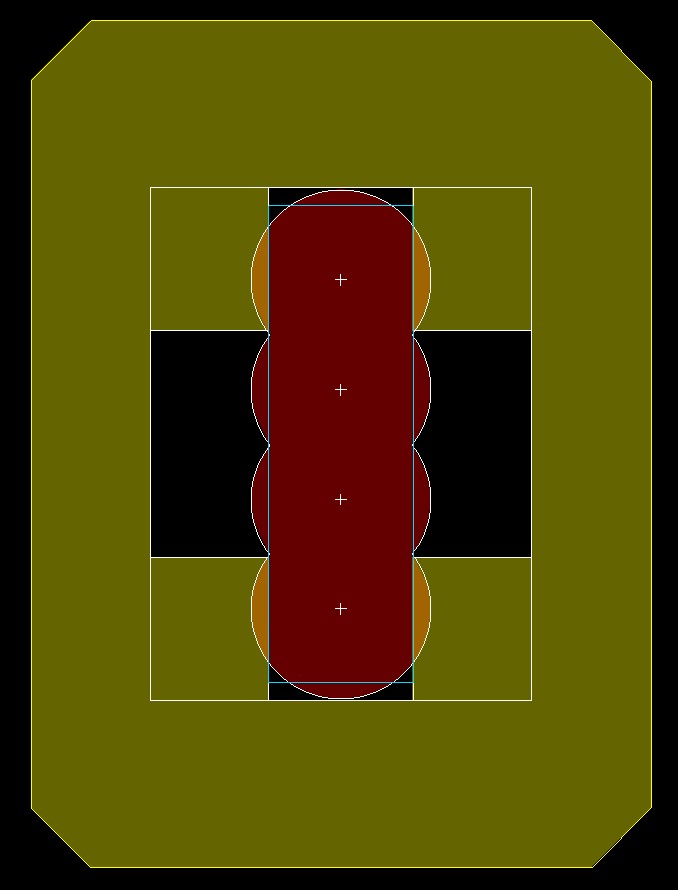

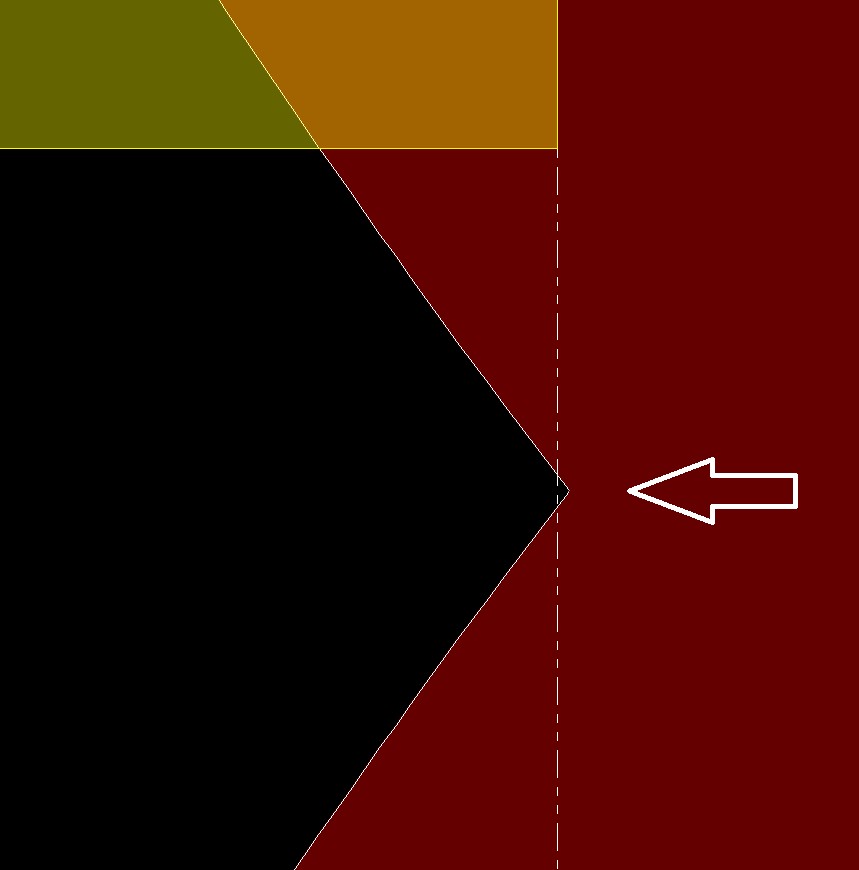

The left one on the middle row is for the three spots along the top edge of the back

The bottom screw goes in the other seven sites.

so just to confirm the 2 centre screws are the original ones on pic 10

Floyd as far as i remember dude the 777 screws are totally different, great offer though, never had a vz2000 so can't confirm on that

. The other stuff is no prob....

. The other stuff is no prob....

....

....

i got a very good TESA......

i got a very good TESA......