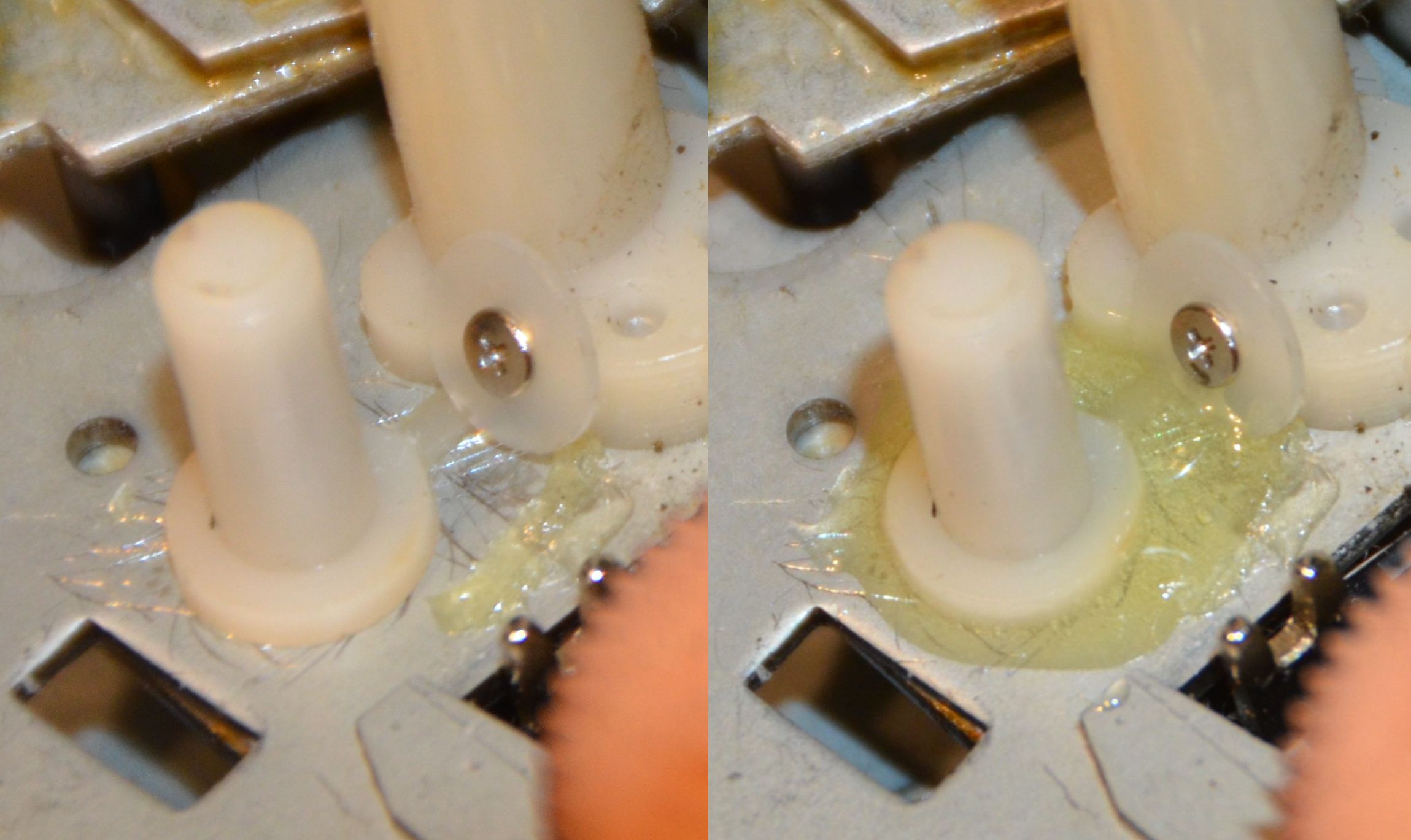

It pulled up after trying it two hours later, double the cure time, but saw the arm was lifting, so I thought, if I could pin that down somehow, then the JB would only need to stop lateral movement.

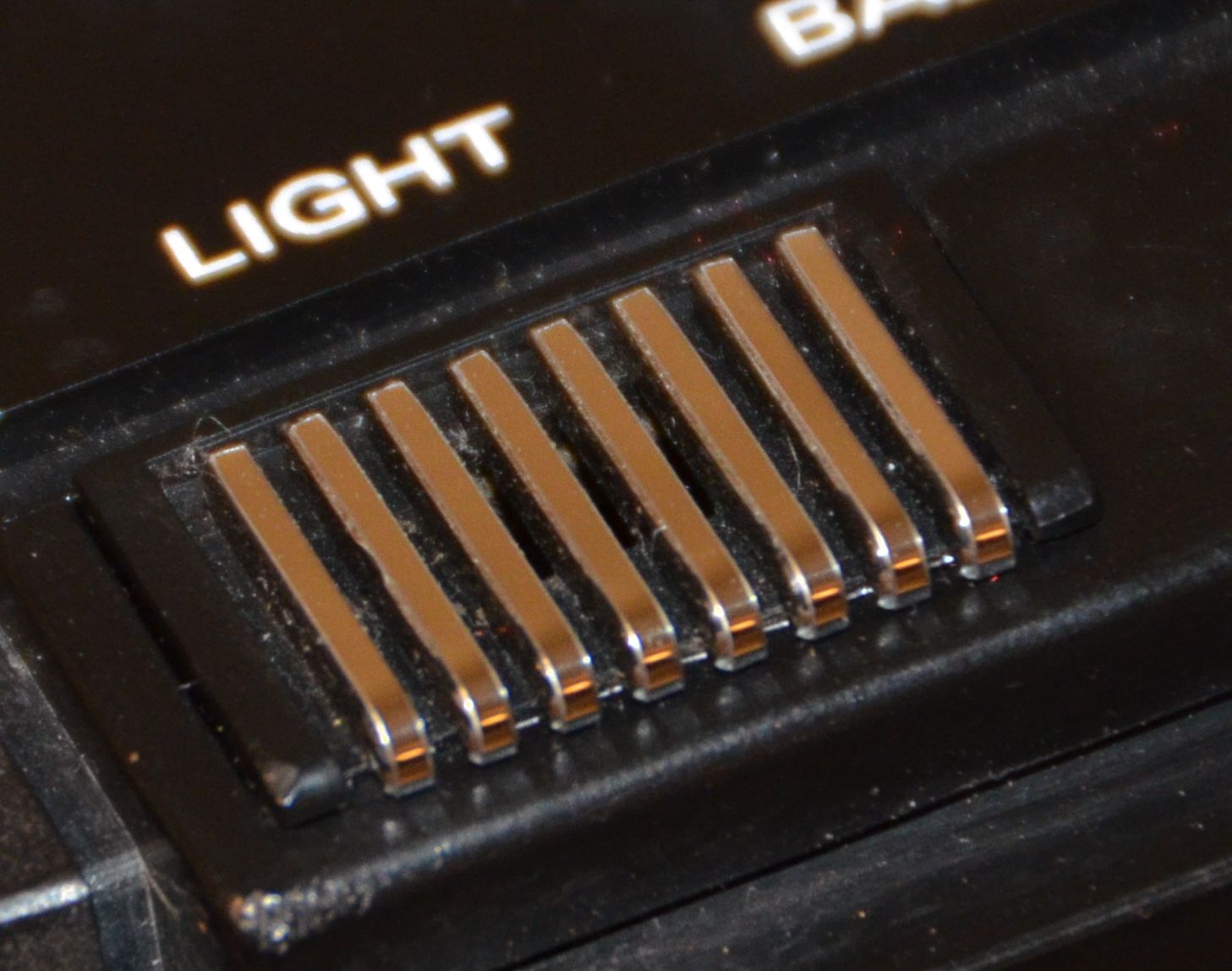

I drilled a 70 gauge (0.028" dia.) hole and used one of my smallest screws, closest OD is an m0.7 or 000-120 but self-tapping. I found a washer thin enough to leave enough shaft to stay in the hole securely and with a hole small enough not to let the head slip through, and large enough to reach the arm since my hole ended up a little high.

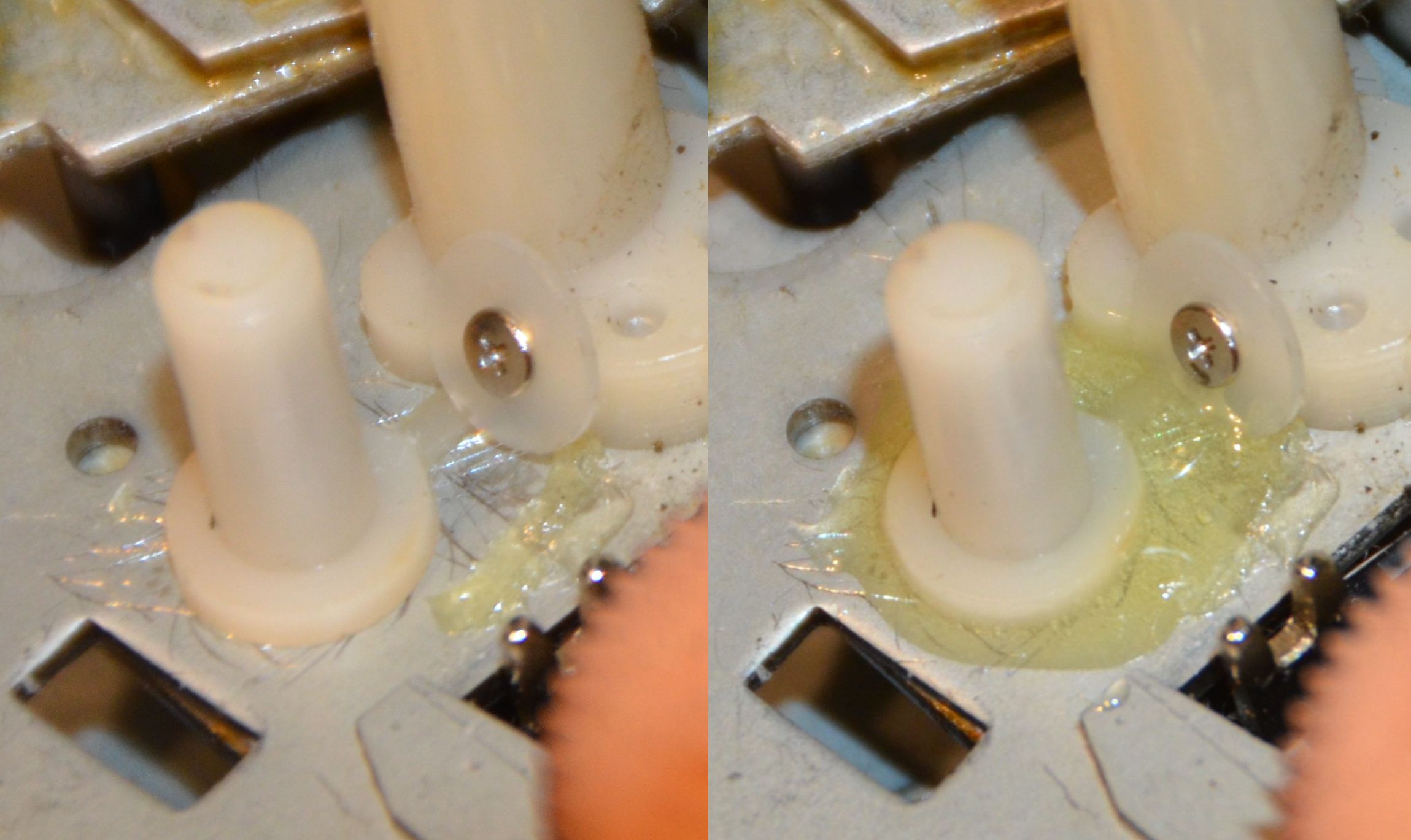

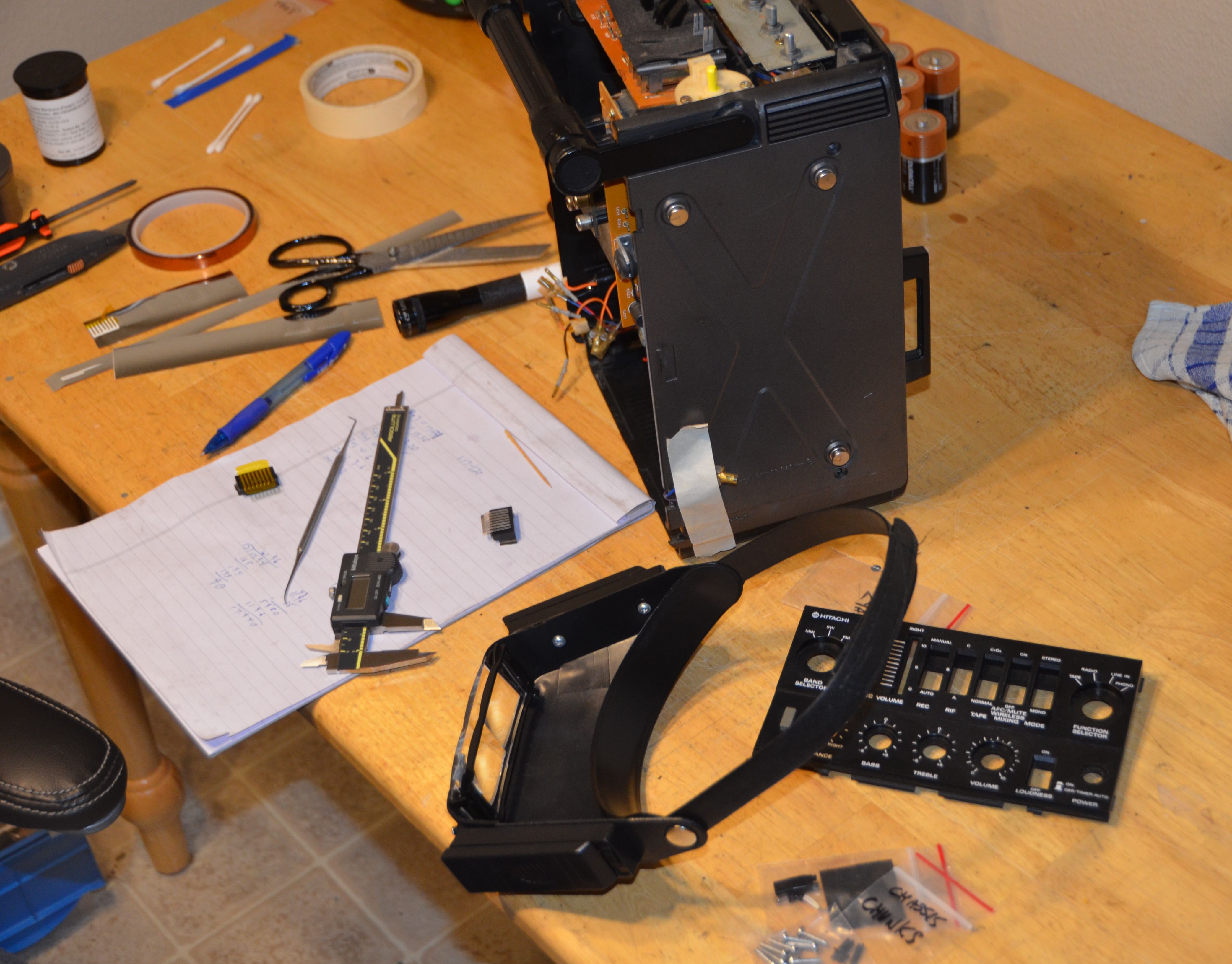

Used some Super Lube on a few spots so it's quiet now, everything apparently works except for rewind auto-stopping. Nothing seems broken so it could be by design.

I drilled a 70 gauge (0.028" dia.) hole and used one of my smallest screws, closest OD is an m0.7 or 000-120 but self-tapping. I found a washer thin enough to leave enough shaft to stay in the hole securely and with a hole small enough not to let the head slip through, and large enough to reach the arm since my hole ended up a little high.

Used some Super Lube on a few spots so it's quiet now, everything apparently works except for rewind auto-stopping. Nothing seems broken so it could be by design.

Your work always amazes me bro, and hardmens chrome and red looks killer too! Good to see your still heavy in the game

Your work always amazes me bro, and hardmens chrome and red looks killer too! Good to see your still heavy in the game