Hello there!

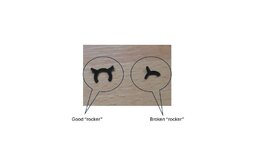

I am repairing an old and rare Siemens RD 127. It's a combi machine with radio, cd and double cassette. There is a problem with 1 of the cassette players: the autostop constantly activates, even with a tape in the player. It seems that there needs to be a "rocker" with very small notches on the take-up reel. During playback this rocker's notches are pushing on the autostop mechanism, preventing it to be activated. One player has this rocker and is working fine; the other one hasn't: I found a broken bit elsewhere inside the unit.

The million dollar question: where can I get this part? Or anyone suggestions how to fabricate one myself?

I am repairing an old and rare Siemens RD 127. It's a combi machine with radio, cd and double cassette. There is a problem with 1 of the cassette players: the autostop constantly activates, even with a tape in the player. It seems that there needs to be a "rocker" with very small notches on the take-up reel. During playback this rocker's notches are pushing on the autostop mechanism, preventing it to be activated. One player has this rocker and is working fine; the other one hasn't: I found a broken bit elsewhere inside the unit.

The million dollar question: where can I get this part? Or anyone suggestions how to fabricate one myself?