I agree that your loops are probably better able to withstand sideways impacts, compared to the Crown which did not have any "give".

The concern I have is that you drilled the holes....They were not molded into the case by the manufacturer. Drilling would seem to pose risks of future stress cracks, since the hole is not perfectly smooth.

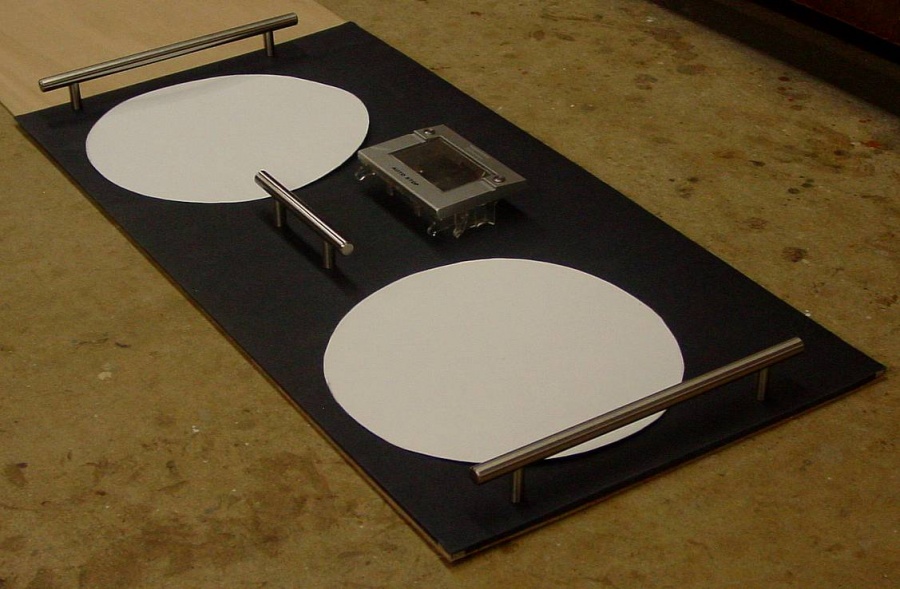

If you want to add more strength, I would recommend adding a flat steel bar between the 2 washers. And then putting some rubber between that bar and the case. This could replace your rubber washers. So you would have, from top to bottom, the plastic case, a long piece of rubber under it, a flat metal bar, and your screws. The rubber would be sandwiched between the case and the flat metal bar. So that when you pick up the boombox, the load is better distributed inside the case. That is what Crown did. The only reason it broke is because the rollbar was smashed in a downward direction, which you can't do much about. But at least with an internal flat bar you could protect it from forces in other directions.

I think for picking the thing straight up with both hands, the handles should work well. Putting a strap on and carrying it around by the strap would put strong side ways stresses on the bars and will over time IMHO result in cracks forming in the case. This is obviously just my opinion but with the weight of the 777, and the long length of your roll bars, the stresses would be quite high. I certainly wouldn't pick it up by one rollbar alone. It is afterall, a thin cased boombox.

I think for picking the thing straight up with both hands, the handles should work well. Putting a strap on and carrying it around by the strap would put strong side ways stresses on the bars and will over time IMHO result in cracks forming in the case. This is obviously just my opinion but with the weight of the 777, and the long length of your roll bars, the stresses would be quite high. I certainly wouldn't pick it up by one rollbar alone. It is afterall, a thin cased boombox.

. There is no way i would risk handling the heavy boomer in this setup. The plastic on top is really tiny too. Huge flat plate inside will help a lot. Still i think the plastic is quite thin for that. It would work just if the bars are going some way all round to the bottom too ( of course connected there too ) . For look is

. There is no way i would risk handling the heavy boomer in this setup. The plastic on top is really tiny too. Huge flat plate inside will help a lot. Still i think the plastic is quite thin for that. It would work just if the bars are going some way all round to the bottom too ( of course connected there too ) . For look is  though. Love it .

though. Love it .

I've actually picked it up by the handles & carried it around already, without any grunts or groans or flexing plastic at all so far. I even lifted it up & down a few times to see if I could feel some flexing & it feels solid to me.

I've actually picked it up by the handles & carried it around already, without any grunts or groans or flexing plastic at all so far. I even lifted it up & down a few times to see if I could feel some flexing & it feels solid to me.