Hi all.

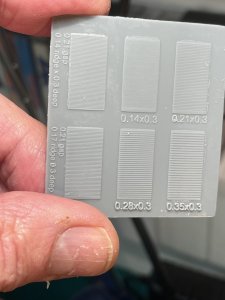

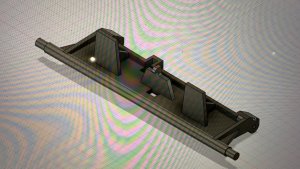

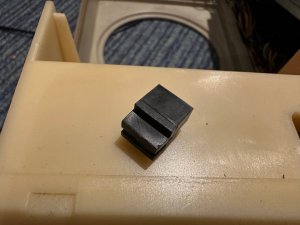

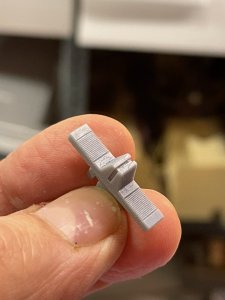

thought I would share these to get some feedback. I have been working to a 3D design for the VZ sliders. Being a perfectionist I have spent many hours tweaking the design and running test prints to try to get them as close as possible to the original. I even bought a new 4K resin printer as wanted to get the best detail possible. I then upgraded the said printer as wasn’t happy with the stock results. I have even purchased some airbrushes and compressor to finish them as ordinary spray paint will be too thick . By the time I finish, these will probably be the most expensive sliders ever, but must admit I am enjoying the process.

anyway I think I am getting pretty close to having a final printed version that I think is not too bad. The grooves are not quite as fine as the original, but I have played around with so many tests and this seems to be the optimal size. if I do them any finer you just don’t really see them. Anyway here is an unpainted sample along with the original. Would like to get your feedback on what you think.

thought I would share these to get some feedback. I have been working to a 3D design for the VZ sliders. Being a perfectionist I have spent many hours tweaking the design and running test prints to try to get them as close as possible to the original. I even bought a new 4K resin printer as wanted to get the best detail possible. I then upgraded the said printer as wasn’t happy with the stock results. I have even purchased some airbrushes and compressor to finish them as ordinary spray paint will be too thick . By the time I finish, these will probably be the most expensive sliders ever, but must admit I am enjoying the process.

anyway I think I am getting pretty close to having a final printed version that I think is not too bad. The grooves are not quite as fine as the original, but I have played around with so many tests and this seems to be the optimal size. if I do them any finer you just don’t really see them. Anyway here is an unpainted sample along with the original. Would like to get your feedback on what you think.

Attachments

-

D0F01440-EABE-4EEA-9C9B-5BDBEF75A5FC.jpeg106.3 KB · Views: 38

D0F01440-EABE-4EEA-9C9B-5BDBEF75A5FC.jpeg106.3 KB · Views: 38 -

02DF2878-A622-47E5-83E9-182309C7728D.jpeg99.3 KB · Views: 35

02DF2878-A622-47E5-83E9-182309C7728D.jpeg99.3 KB · Views: 35 -

41B5C029-4253-422D-97B8-614CB18D2941.jpeg105.5 KB · Views: 36

41B5C029-4253-422D-97B8-614CB18D2941.jpeg105.5 KB · Views: 36 -

85B861A2-C10A-47E5-A90B-5B8D37E60CDC.jpeg101.9 KB · Views: 38

85B861A2-C10A-47E5-A90B-5B8D37E60CDC.jpeg101.9 KB · Views: 38 -

B25AC350-83B8-4069-A598-8C9D67145A6C.jpeg100.9 KB · Views: 37

B25AC350-83B8-4069-A598-8C9D67145A6C.jpeg100.9 KB · Views: 37