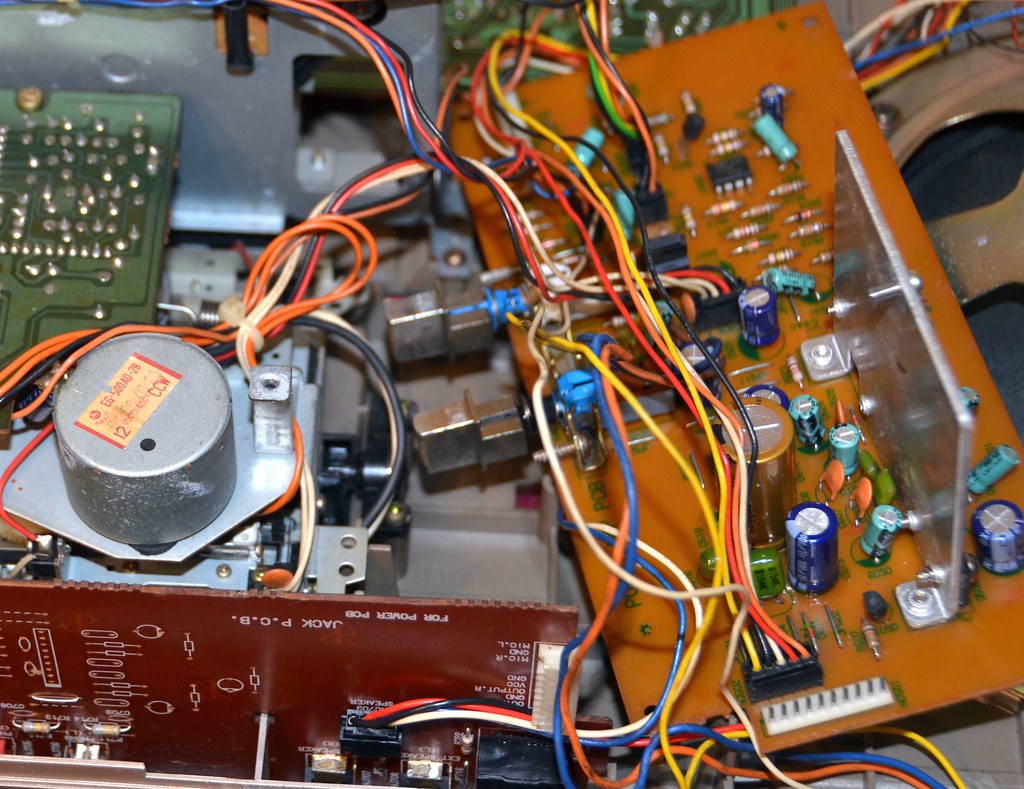

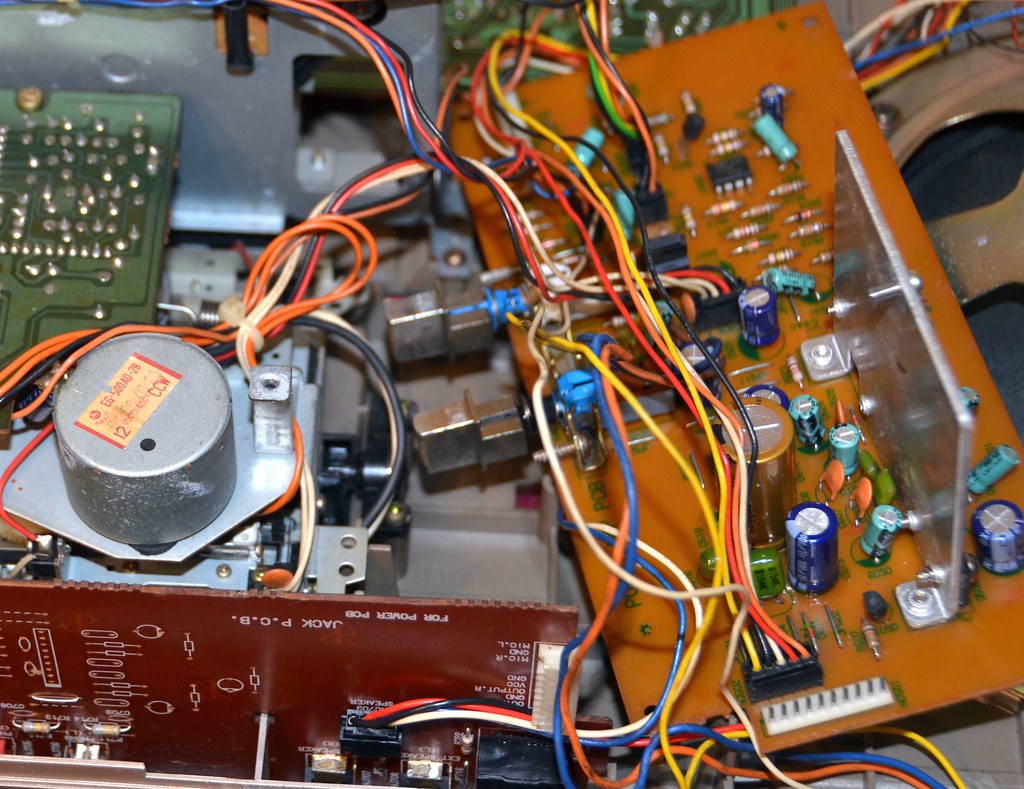

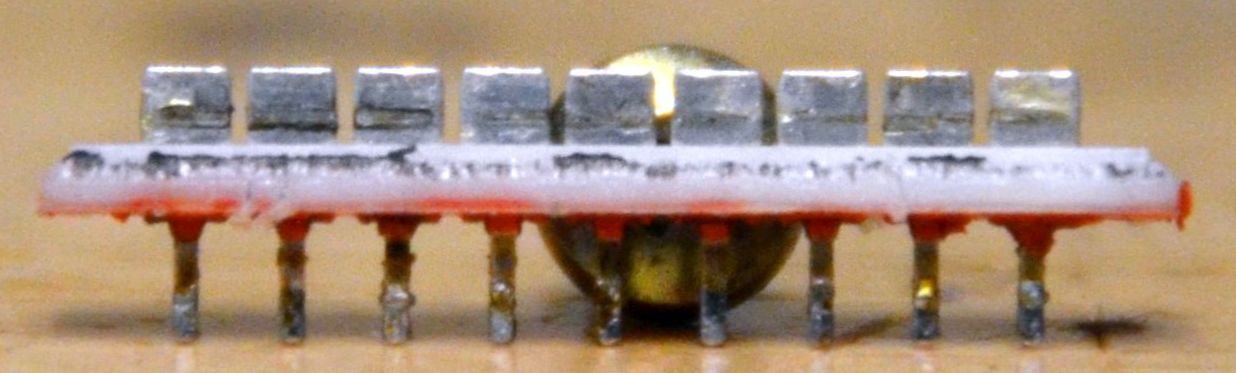

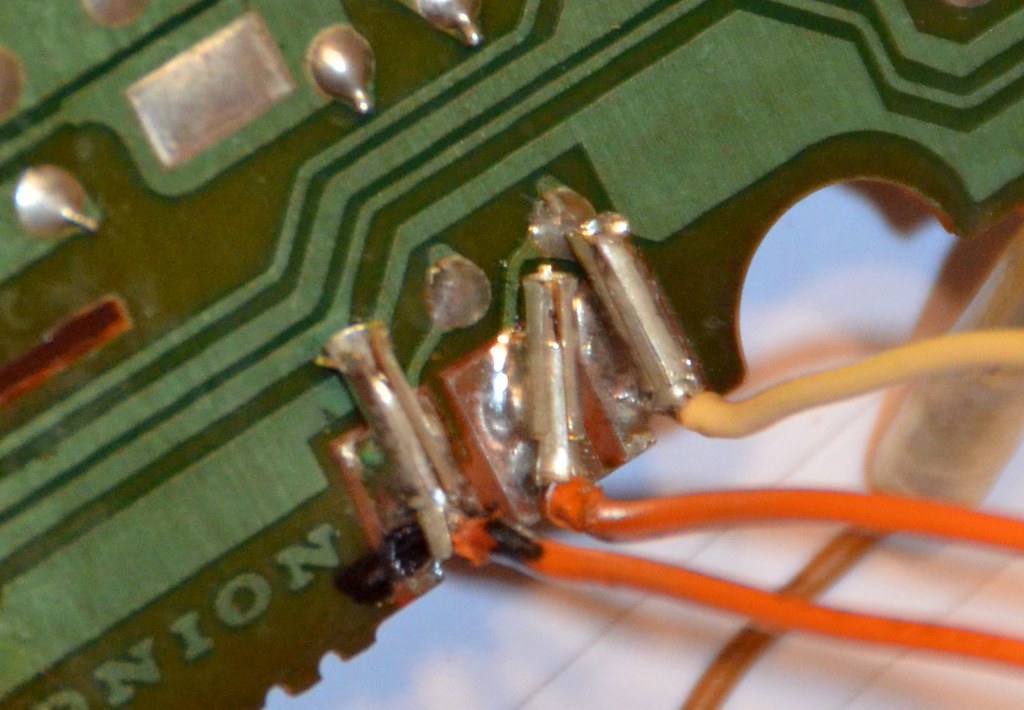

I've been trying to revive a Technisonic TC-999 that would just buzz and fuzz at full volume no matter what you did with the knobs. A new main amp cap didn't fix it, but it was soon evident why. One of the screws holding the heatsink to the amp board was missing, and all three devices mounted to it had solder cracks, probably because the heatsink also mounts to the tape deck motor with a bracket, which probably wiggled it and cracked the joints loose over time. All resoldered, new screw, and sounds great.

Taking the screws out the back I noticed half of them had the wrong thread style, so I managed to find correct replacements, although a bit shorter they hold solid. Then I noticed that the clip anchoring one side of the handle was broken, and wouldn't stay in at all. It's sort of like an arrow that pokes through a hole and stays there, but the fins snapped off. So, I cut the post off that held the clips and drilled some holes in it, then drilled the same pattern in a tiny aluminum plate that now holds it in place.

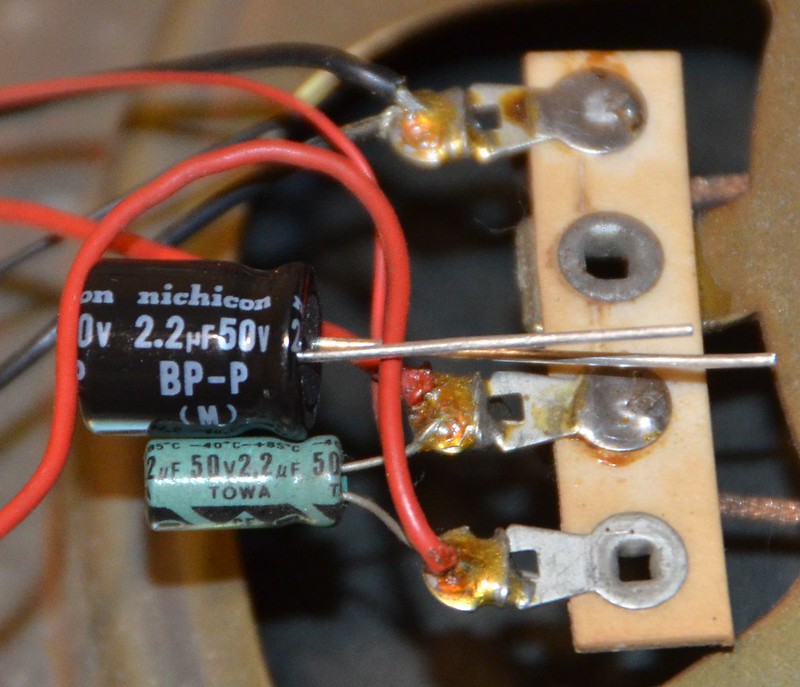

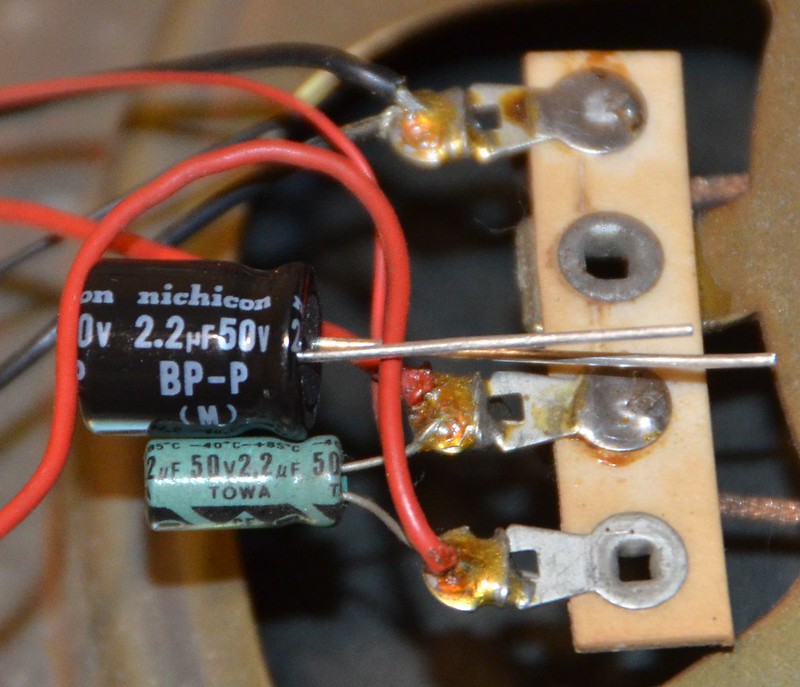

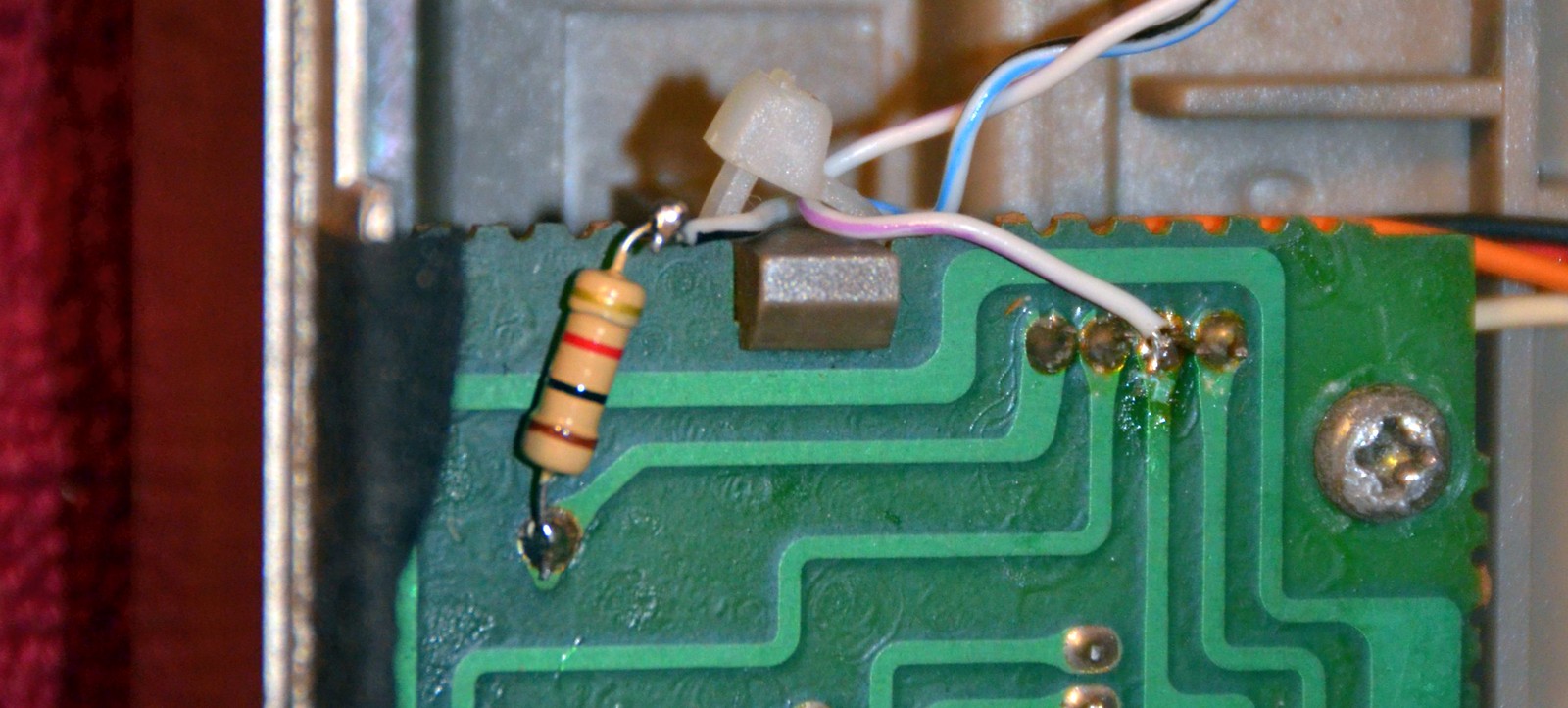

I swapped out the original polarized caps with NP crossover caps and sanded off the rust on all the battery terminals.

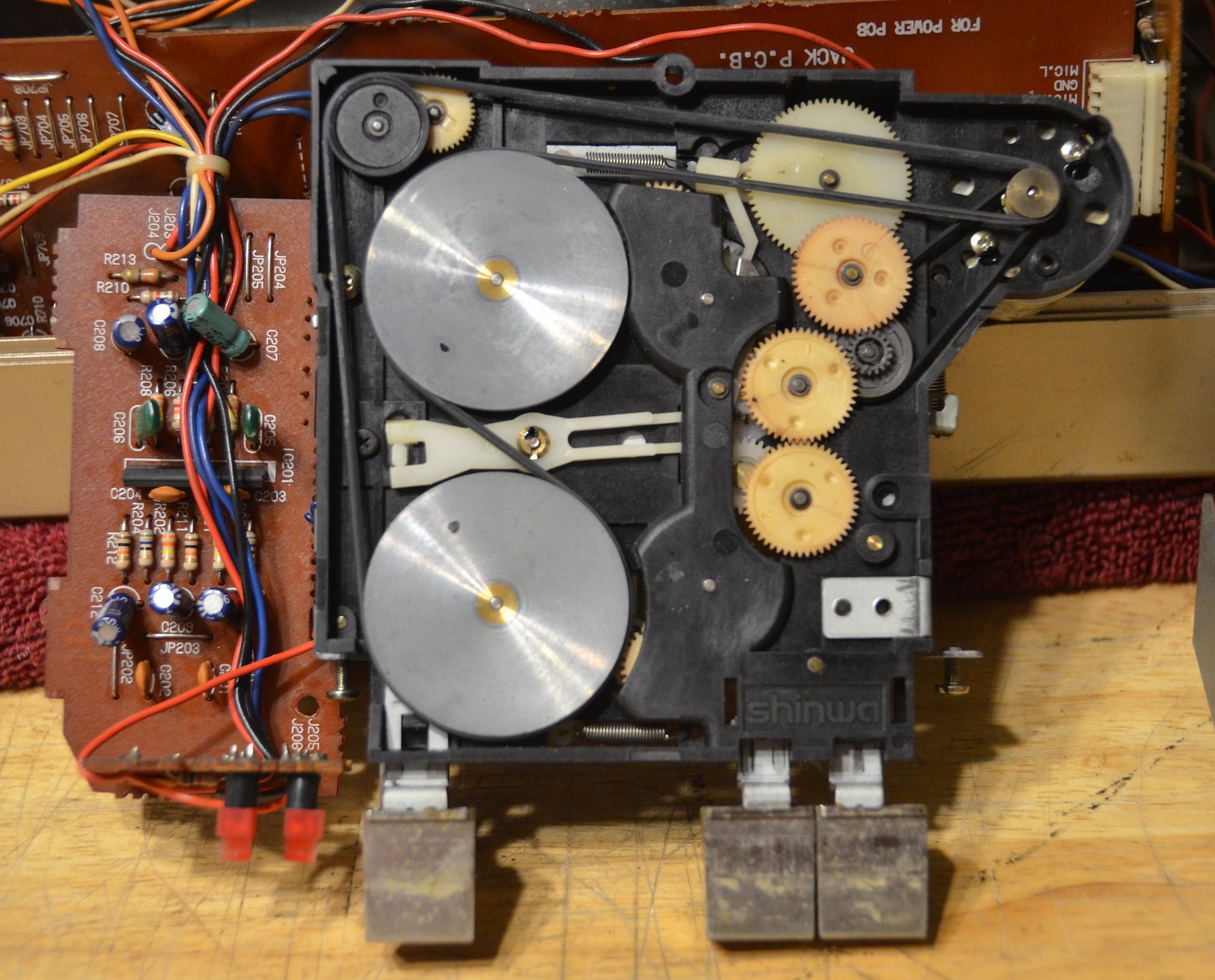

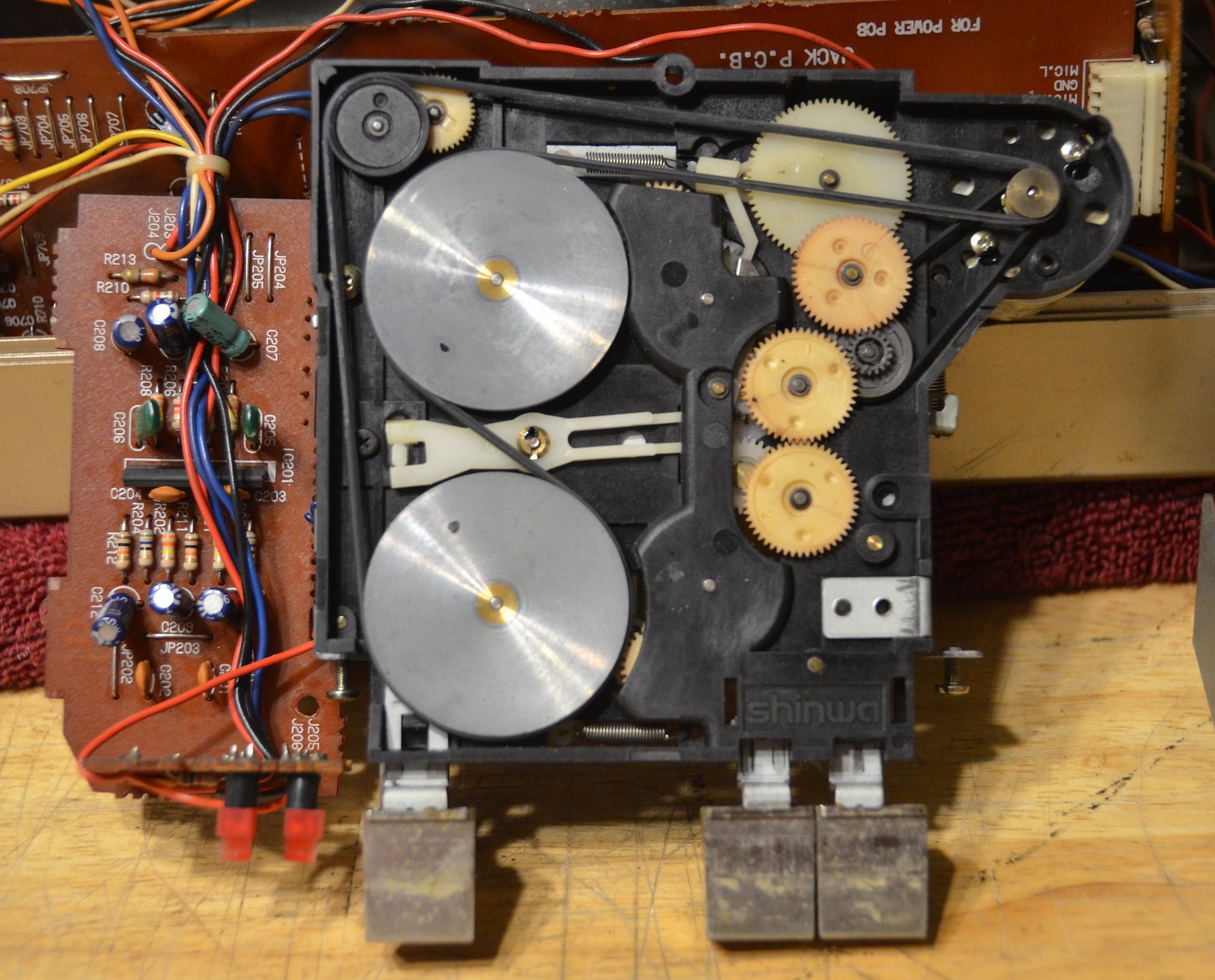

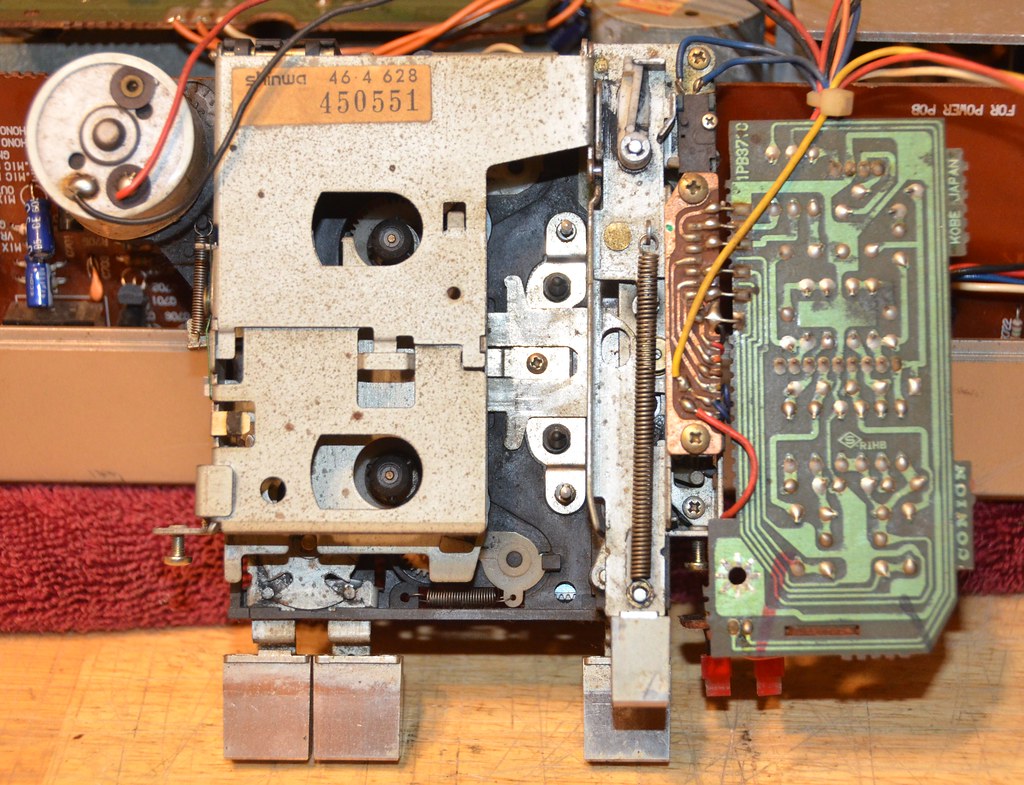

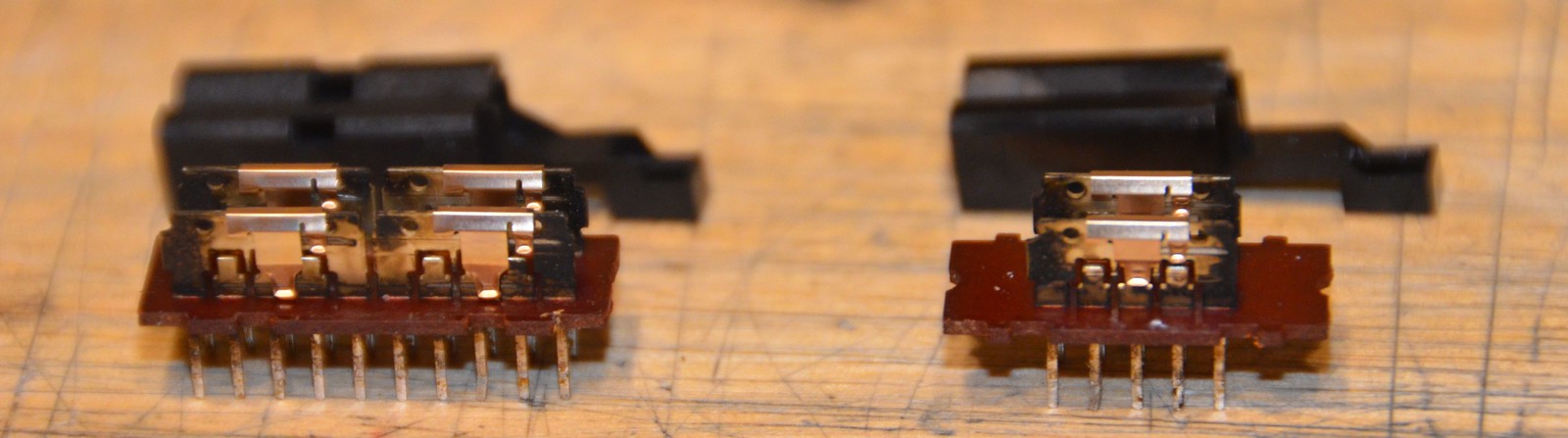

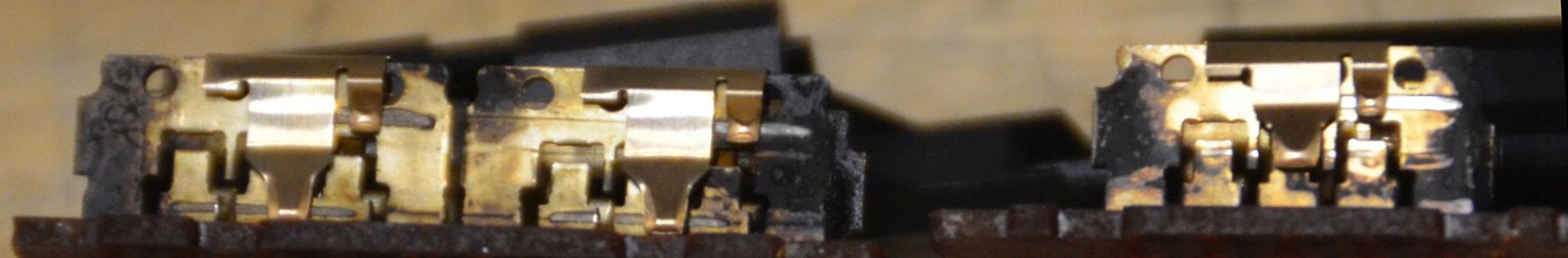

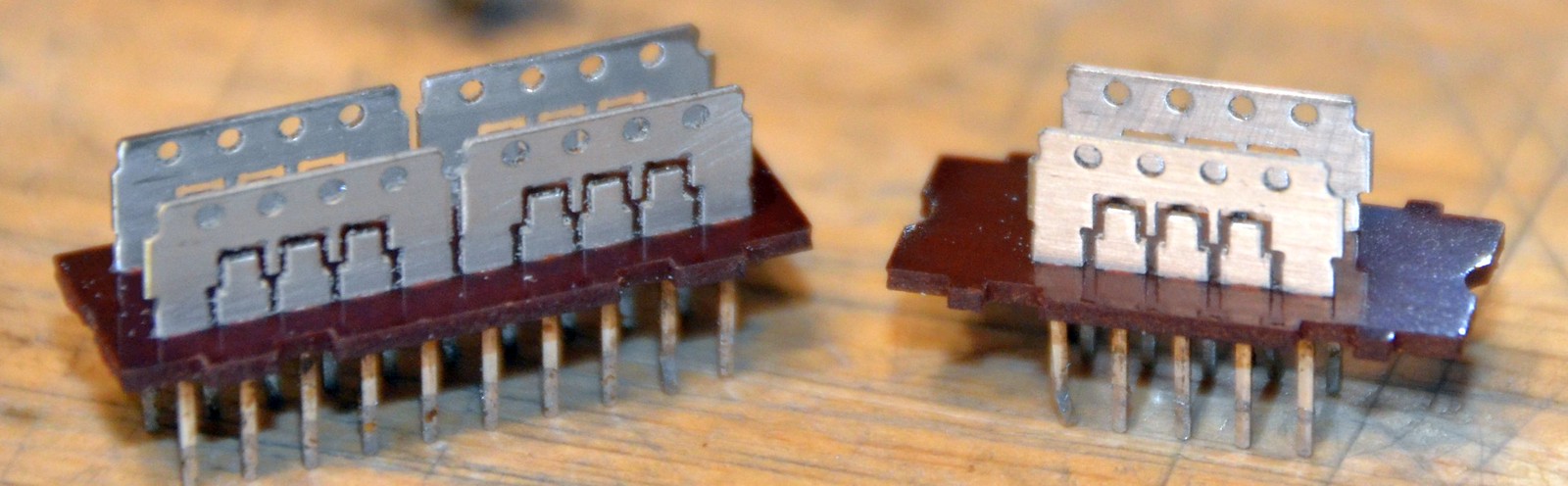

Right now I've got both decks apart and determining which size belts I should replace them with. Not much on the site here that I can find, so I might post about what ends up working best.

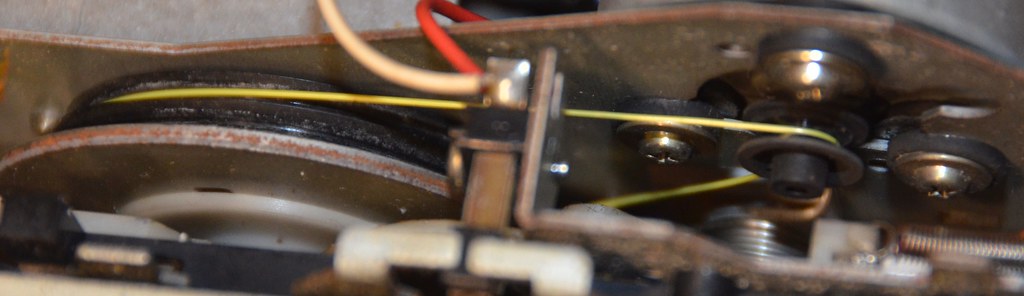

The upper deck has two belts. One is measuring 16" worn, so I'm not sure if I should subtract 10% (1.6") or even 20% (3.2"!) so I'm still noodling over that since each one will cost a bit. You can't get sizes that big in those variety packs on ebay.

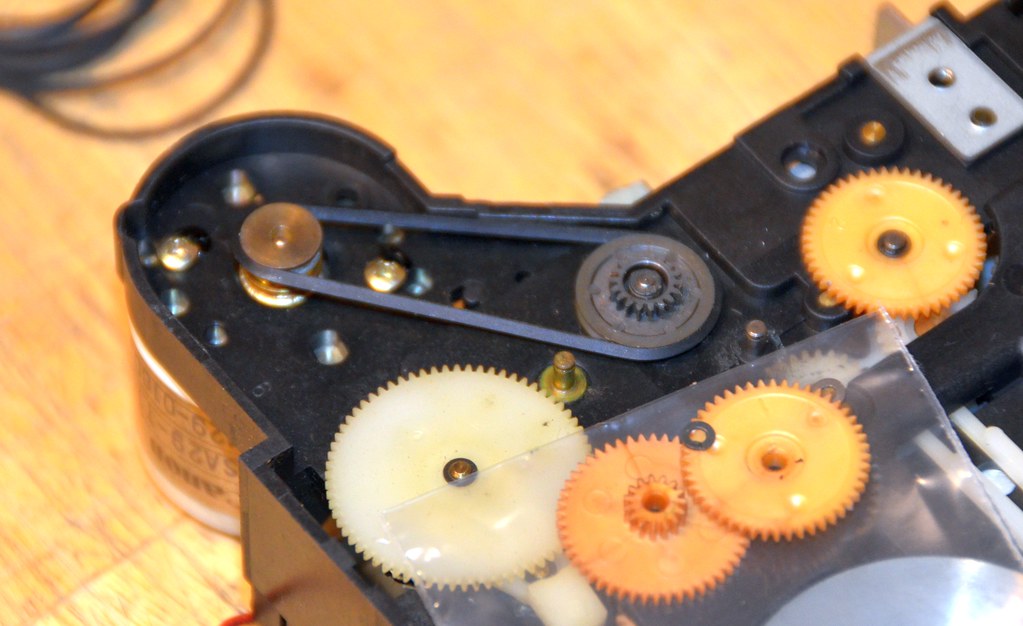

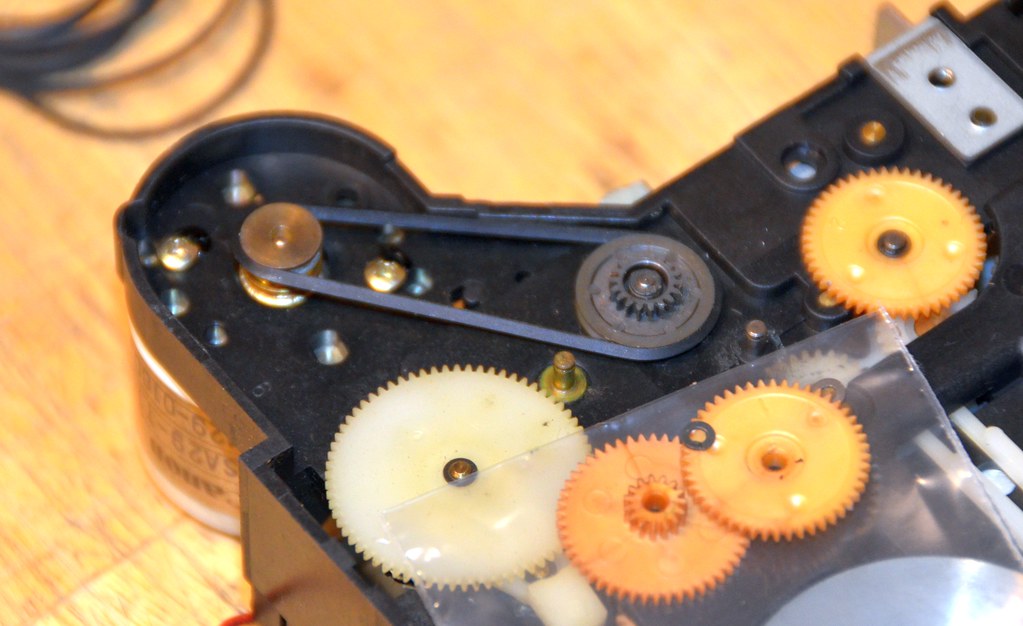

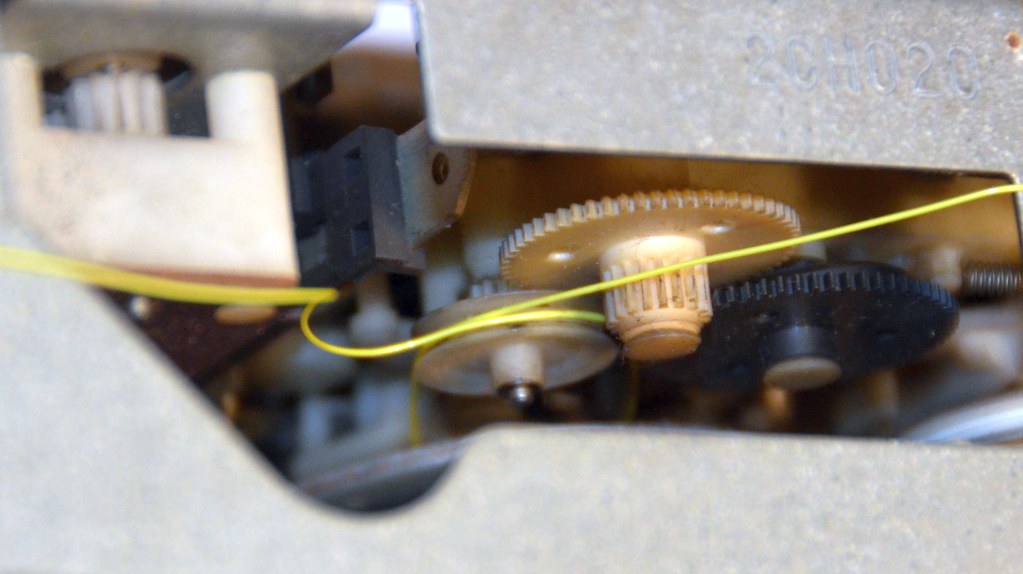

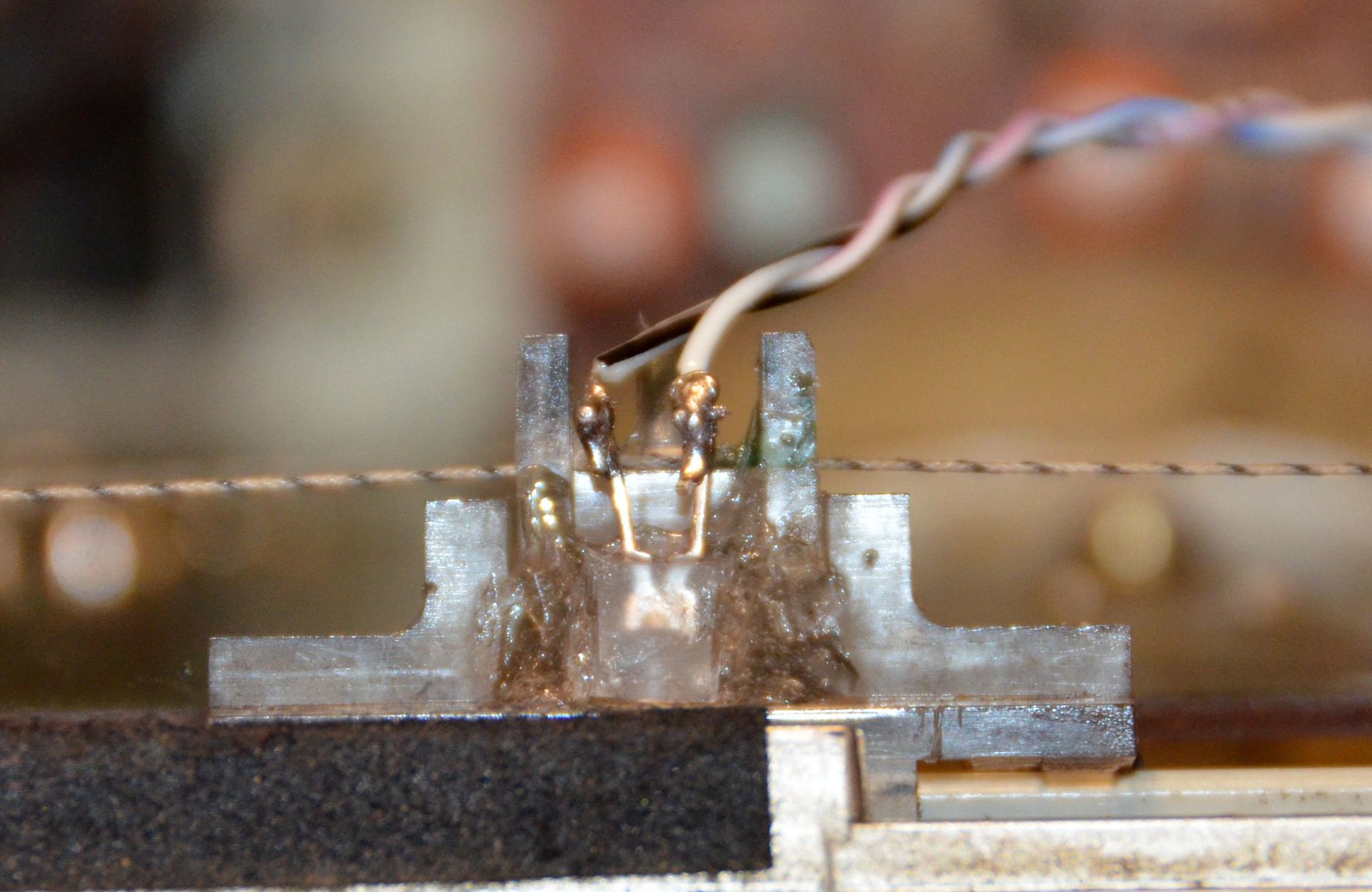

The shorter one is 3.8" worn, and could only be removed if you pop out two gears, which means removing two tiny oil washers, those fragile black things that are difficult to remove without trashing. Luckily I had a few intact ones in that size from other teardowns, so when the second one went flying into air never to be seen again, I had a backup I had a 3.5" belt that fit for the small one, but you can see in the pic that it's sort of fat.

I had a 3.5" belt that fit for the small one, but you can see in the pic that it's sort of fat.

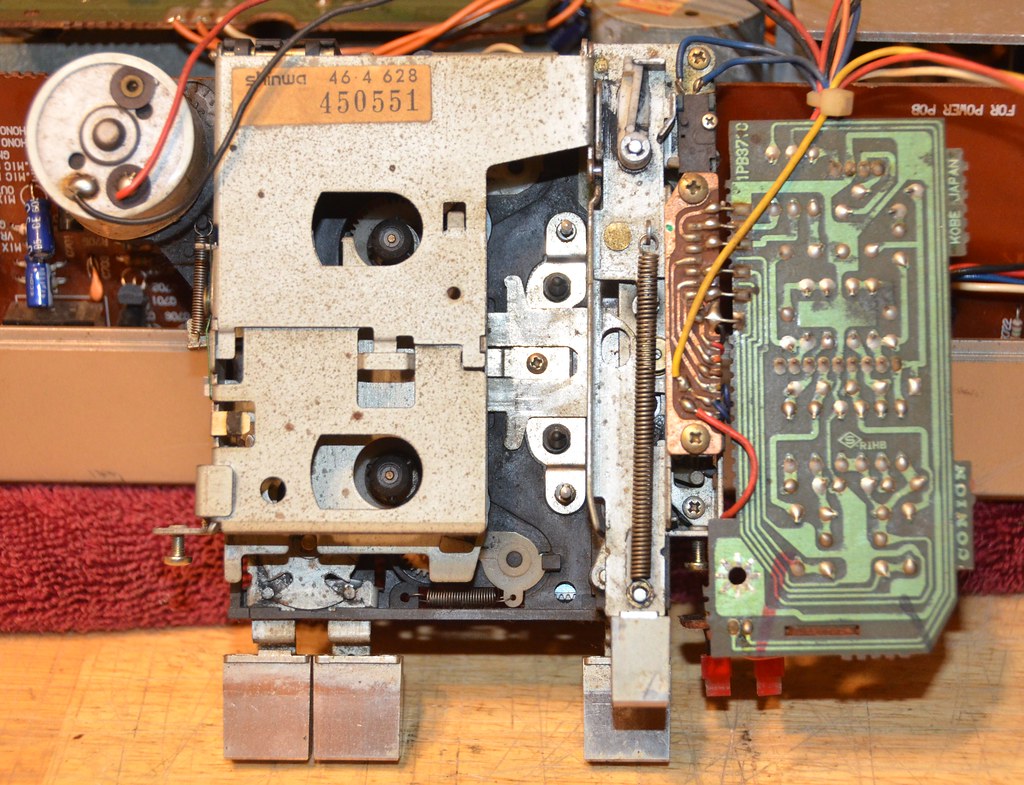

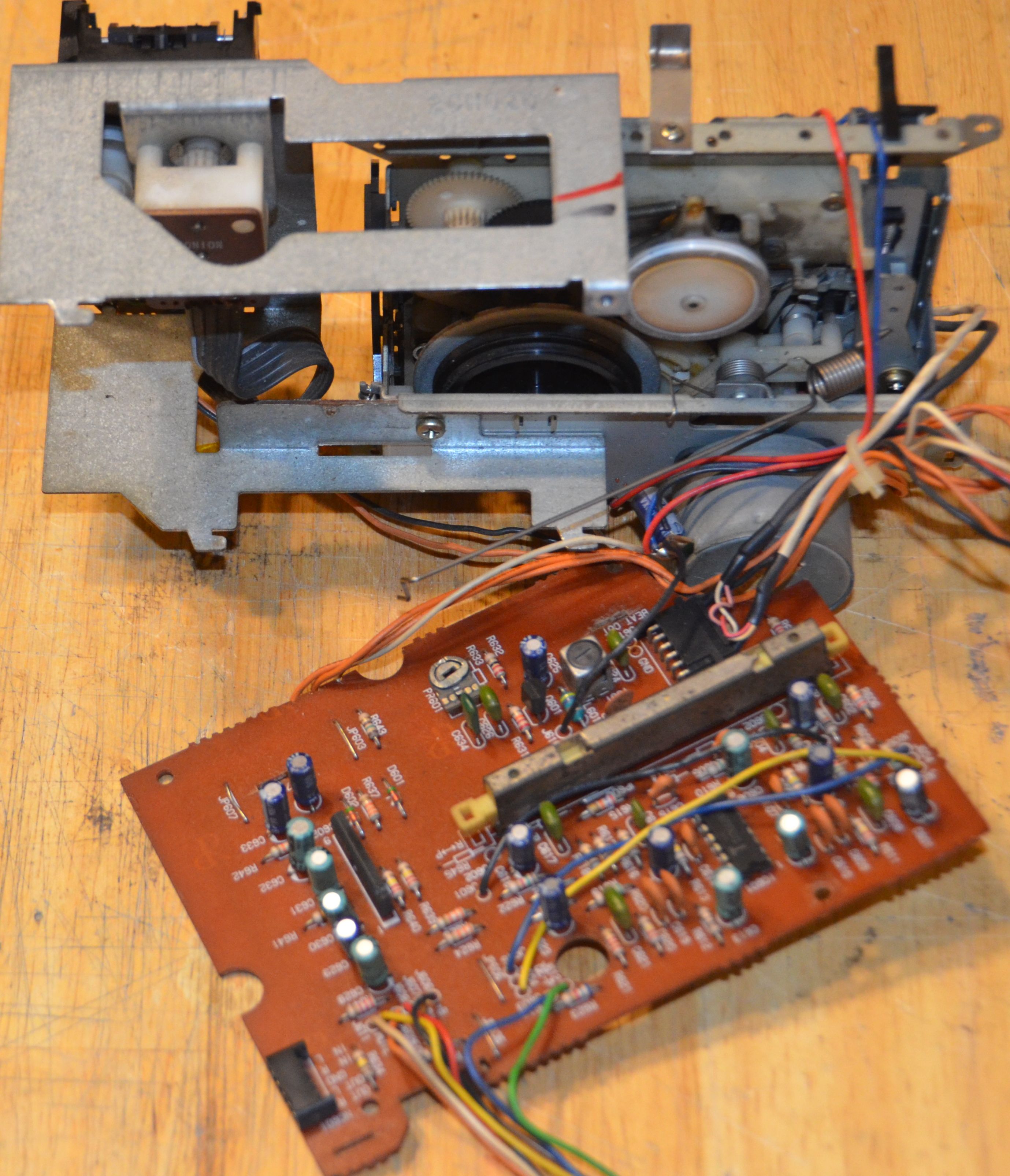

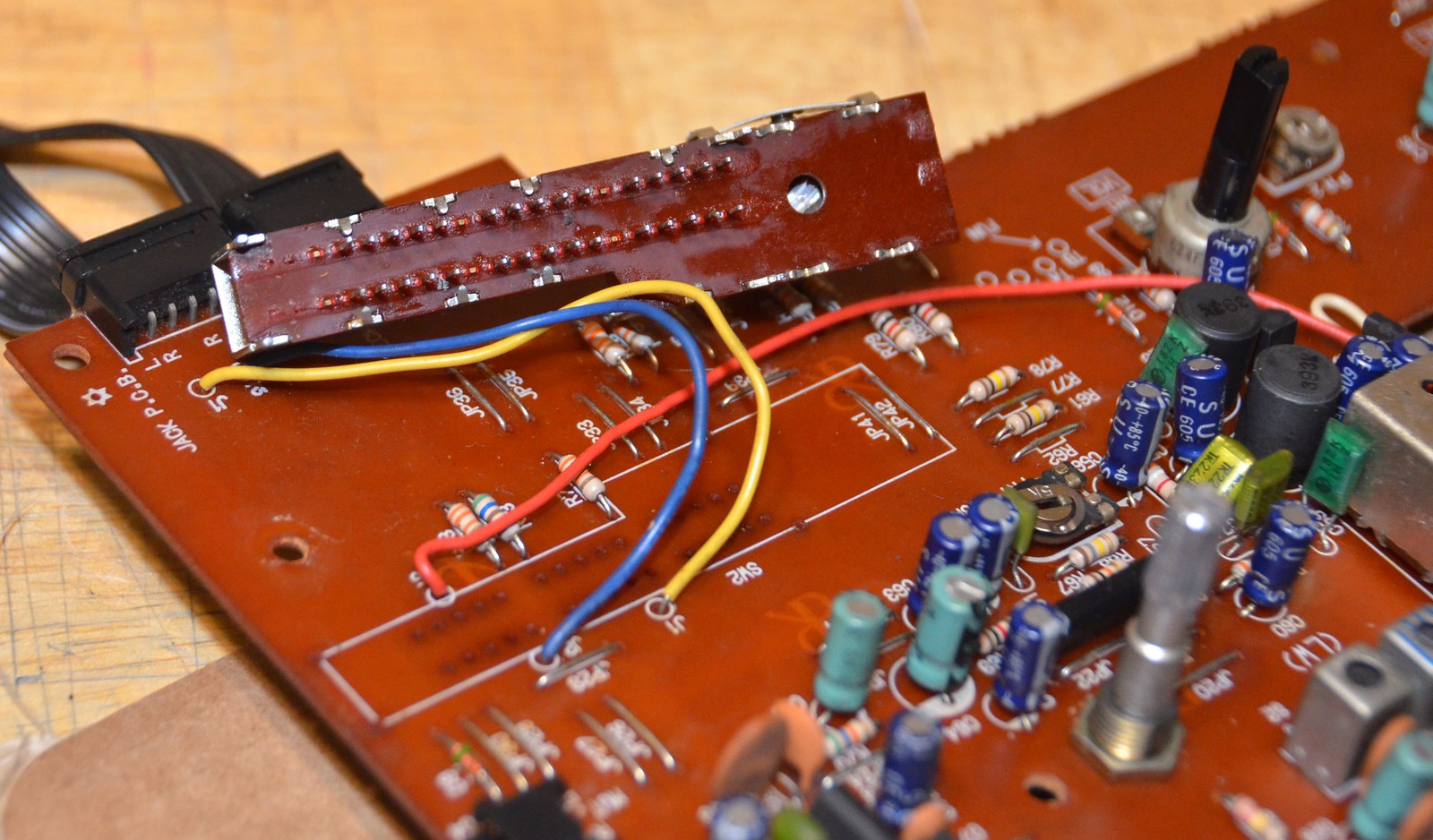

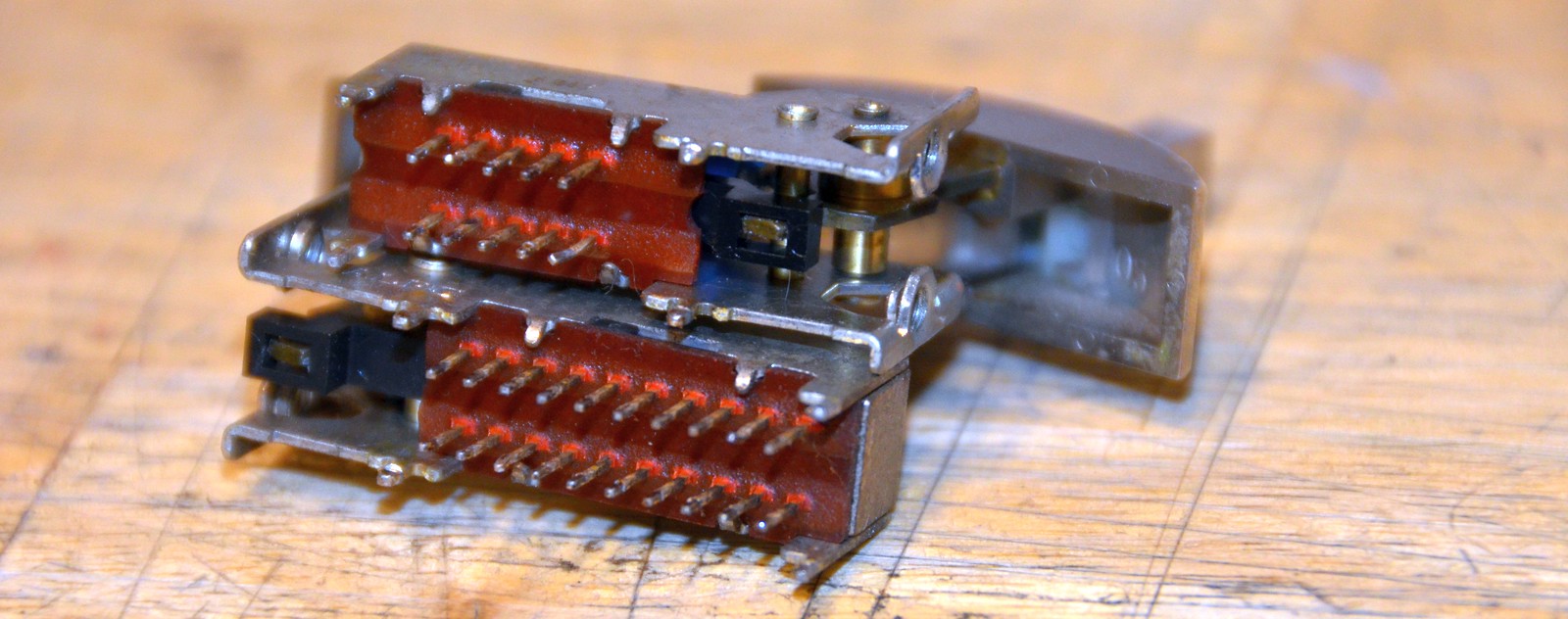

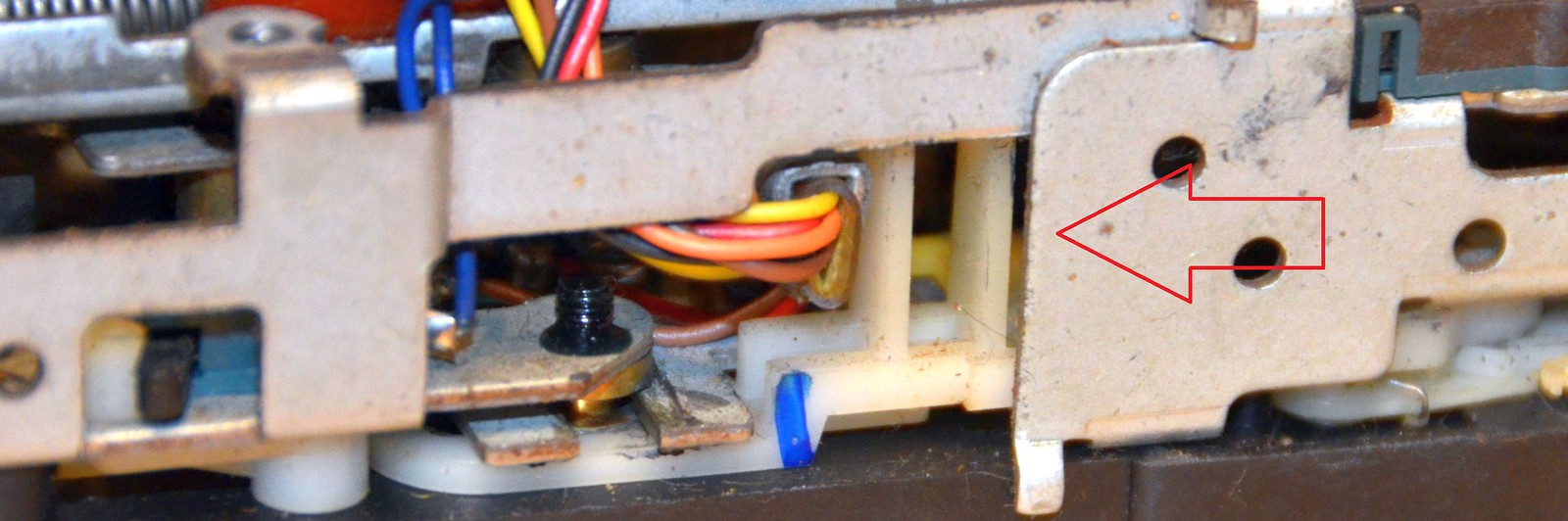

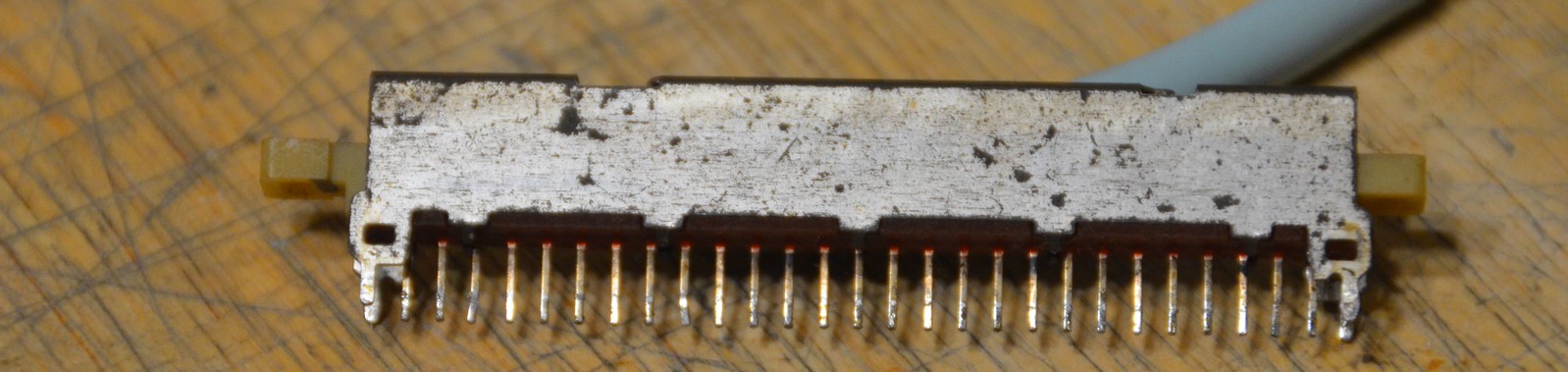

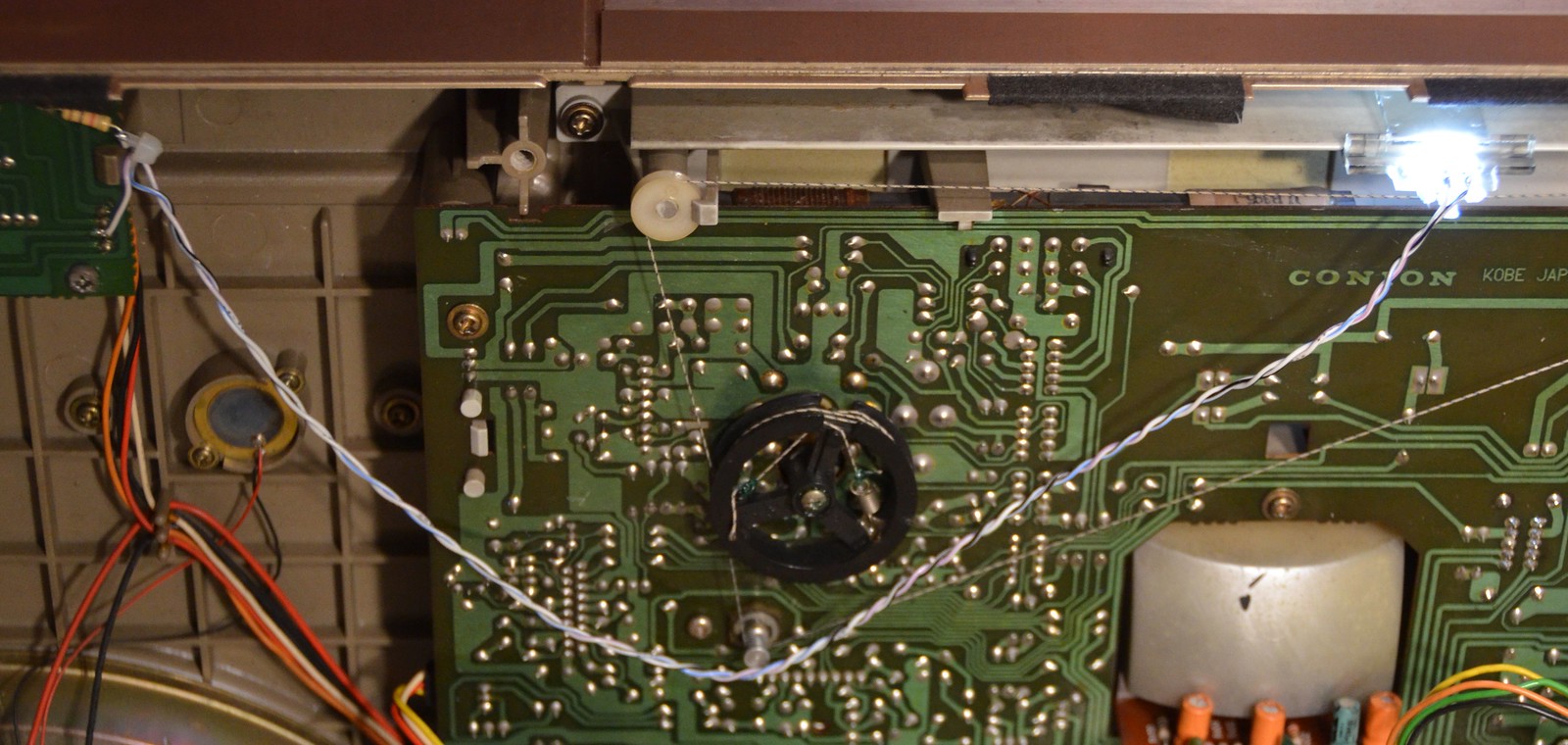

The lower deck has four belts! I am still in the process of tearing it down carefully. Notes, notes, notes. The door must have its eject spring detached from the case inside before the deck will pull out. This is actually a really fun box to work on because every wire it attached to a removable connector.

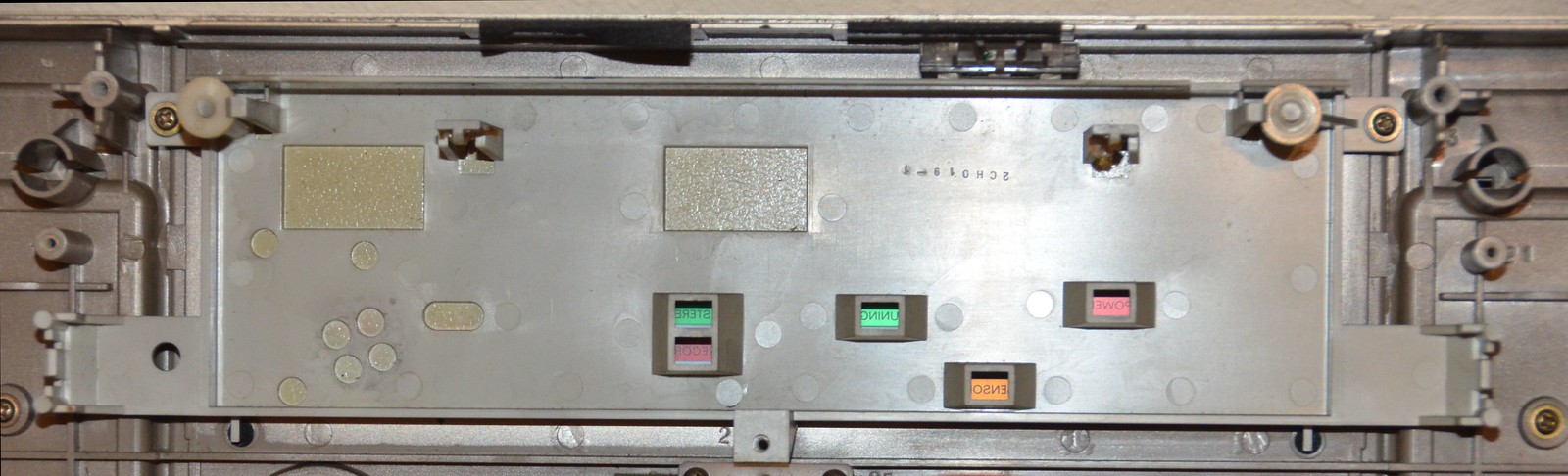

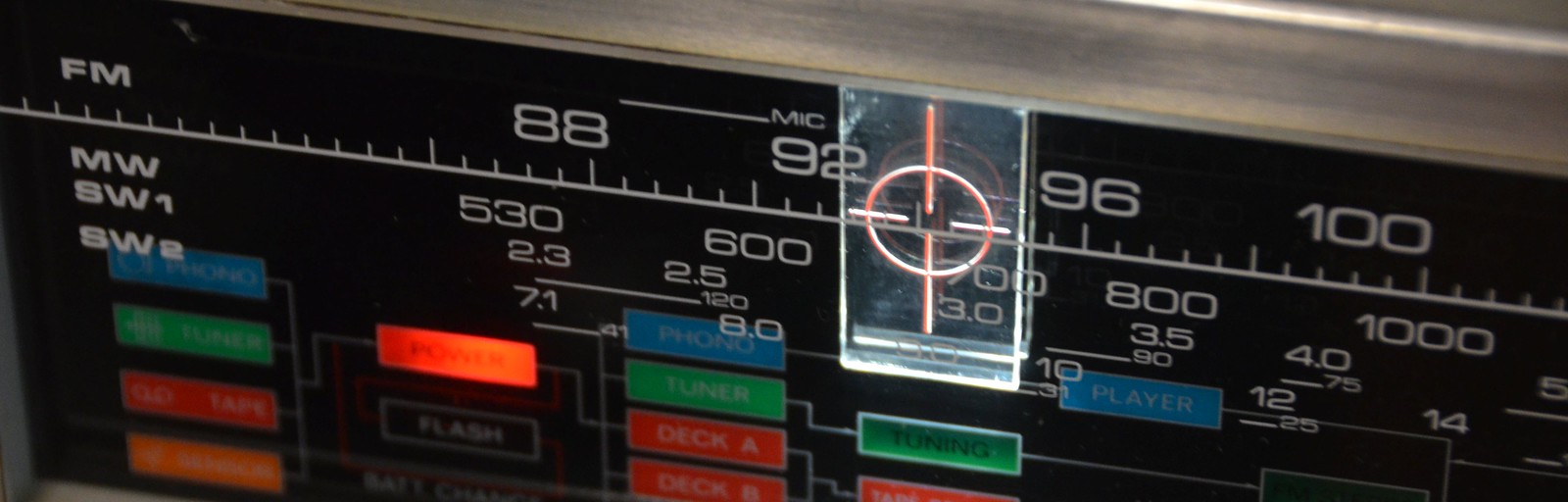

Although that's nice, the function switch and volume knob need cleaning, and they're behind a ginormous tuner-preamp combo board which looks like the dial cord must come off to remove, so that's next.

Shining the flashlight through the back of the amp board looked kind of cool on the logo.

Taking the screws out the back I noticed half of them had the wrong thread style, so I managed to find correct replacements, although a bit shorter they hold solid. Then I noticed that the clip anchoring one side of the handle was broken, and wouldn't stay in at all. It's sort of like an arrow that pokes through a hole and stays there, but the fins snapped off. So, I cut the post off that held the clips and drilled some holes in it, then drilled the same pattern in a tiny aluminum plate that now holds it in place.

I swapped out the original polarized caps with NP crossover caps and sanded off the rust on all the battery terminals.

Right now I've got both decks apart and determining which size belts I should replace them with. Not much on the site here that I can find, so I might post about what ends up working best.

The upper deck has two belts. One is measuring 16" worn, so I'm not sure if I should subtract 10% (1.6") or even 20% (3.2"!) so I'm still noodling over that since each one will cost a bit. You can't get sizes that big in those variety packs on ebay.

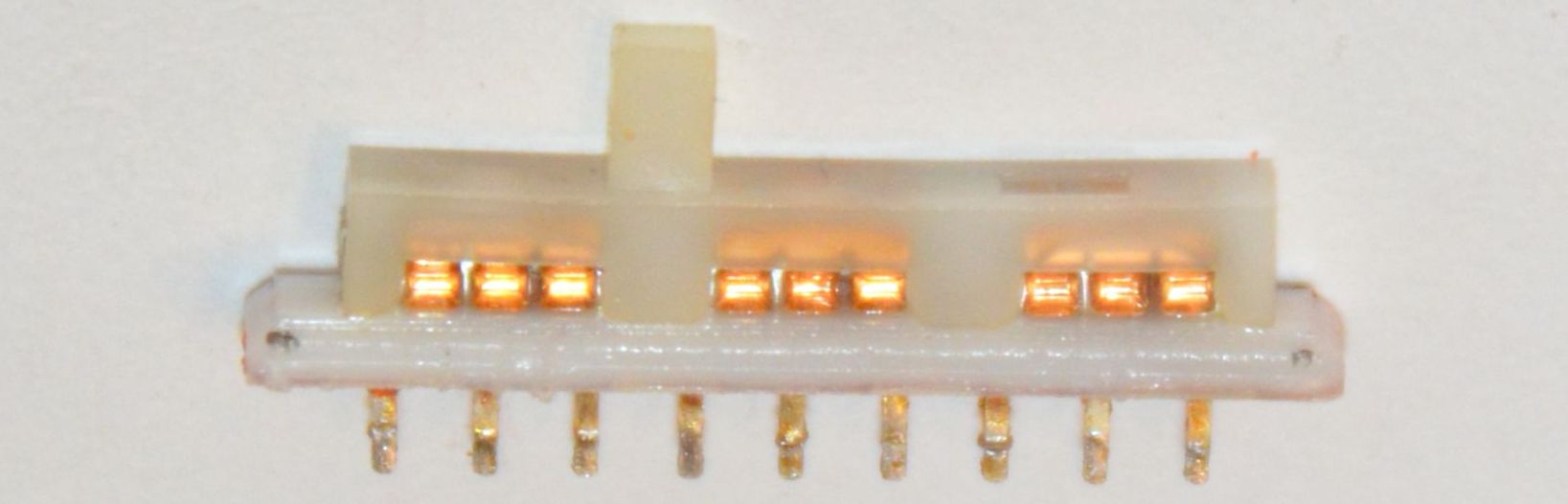

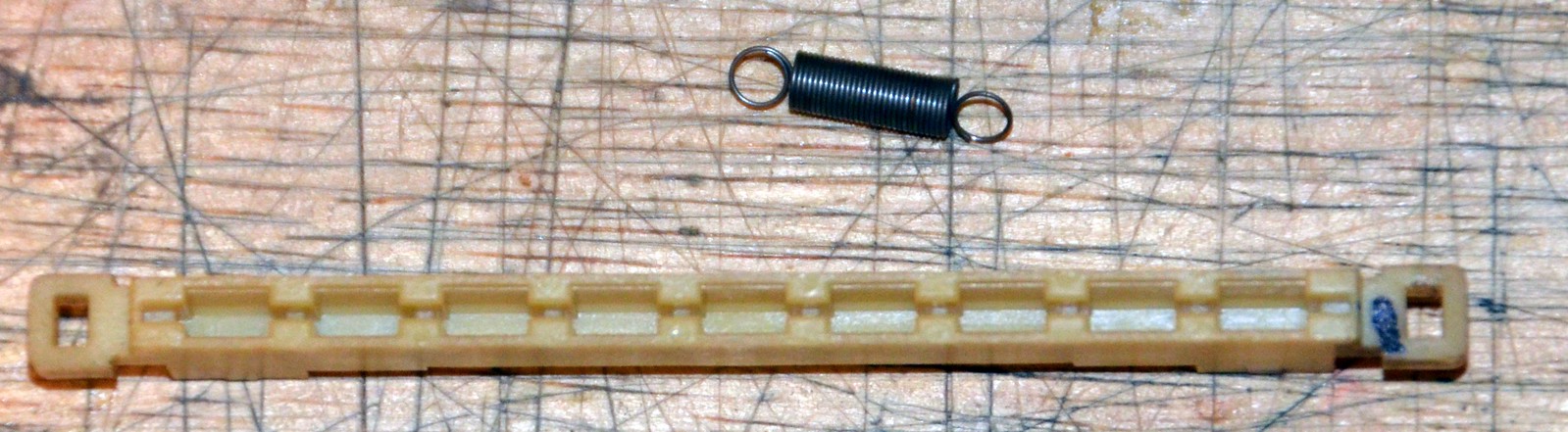

The shorter one is 3.8" worn, and could only be removed if you pop out two gears, which means removing two tiny oil washers, those fragile black things that are difficult to remove without trashing. Luckily I had a few intact ones in that size from other teardowns, so when the second one went flying into air never to be seen again, I had a backup

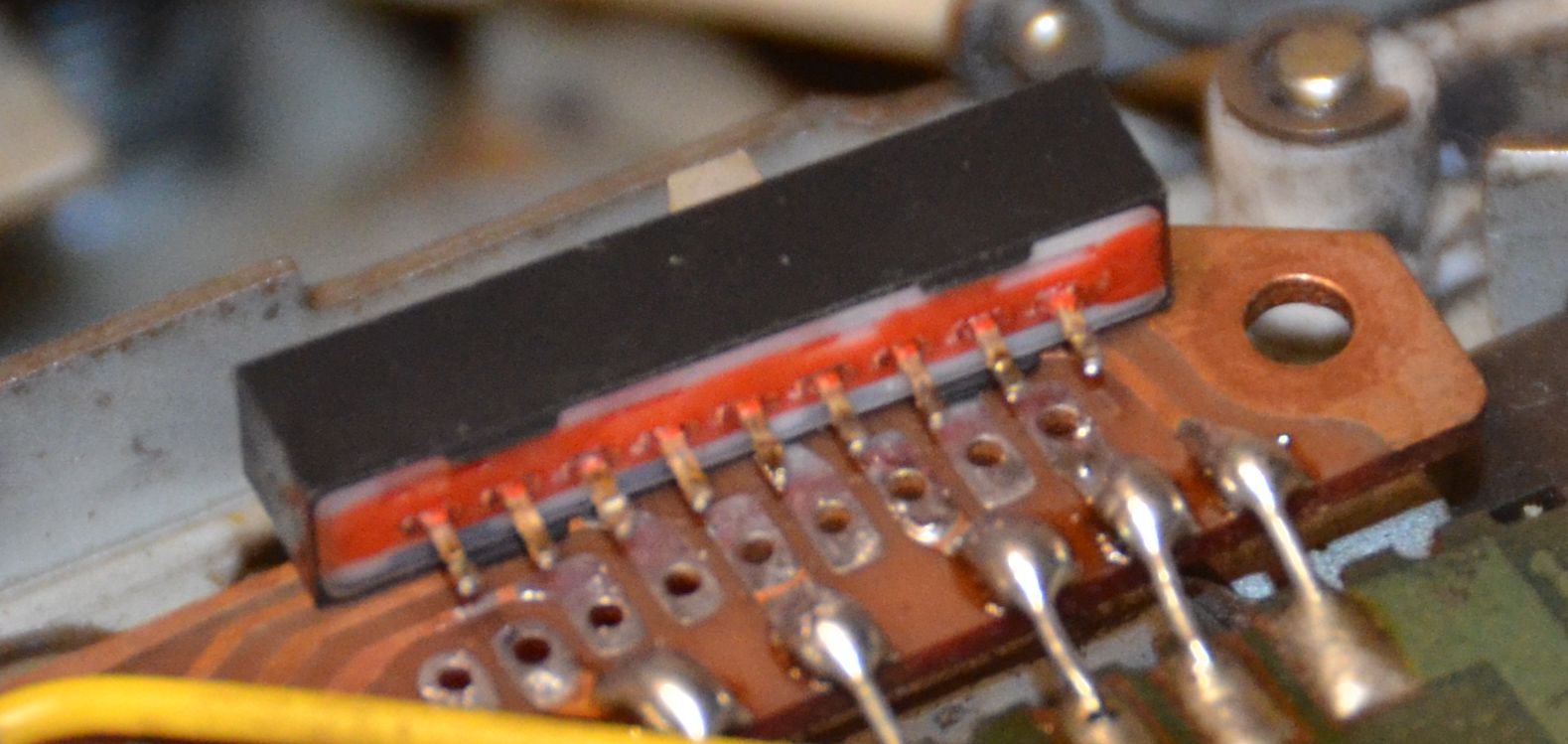

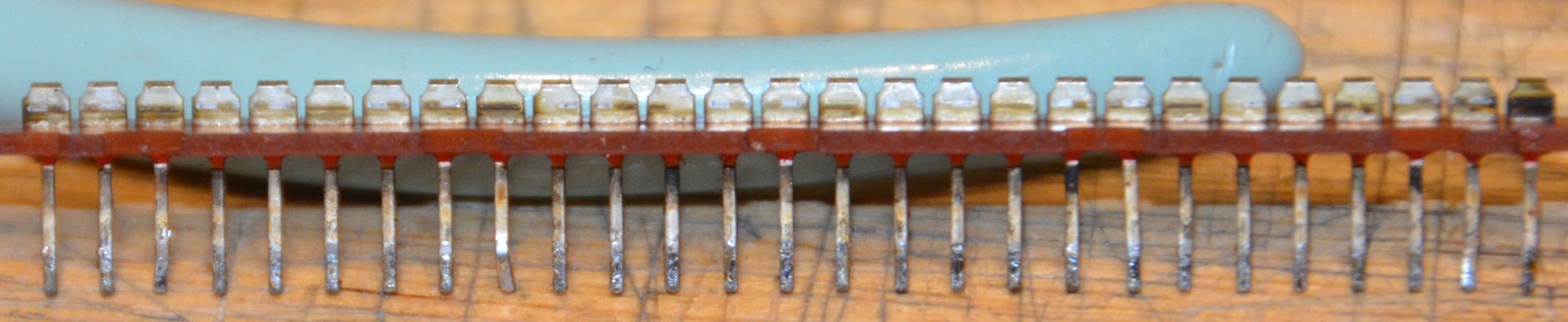

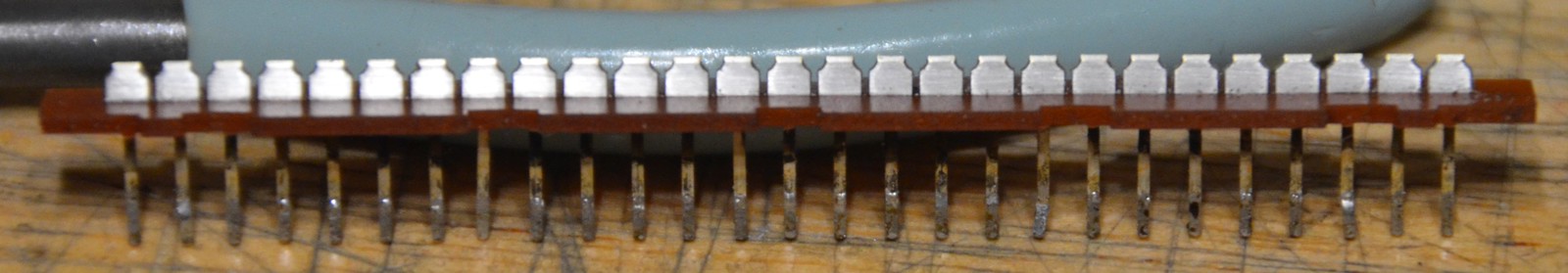

I had a 3.5" belt that fit for the small one, but you can see in the pic that it's sort of fat.

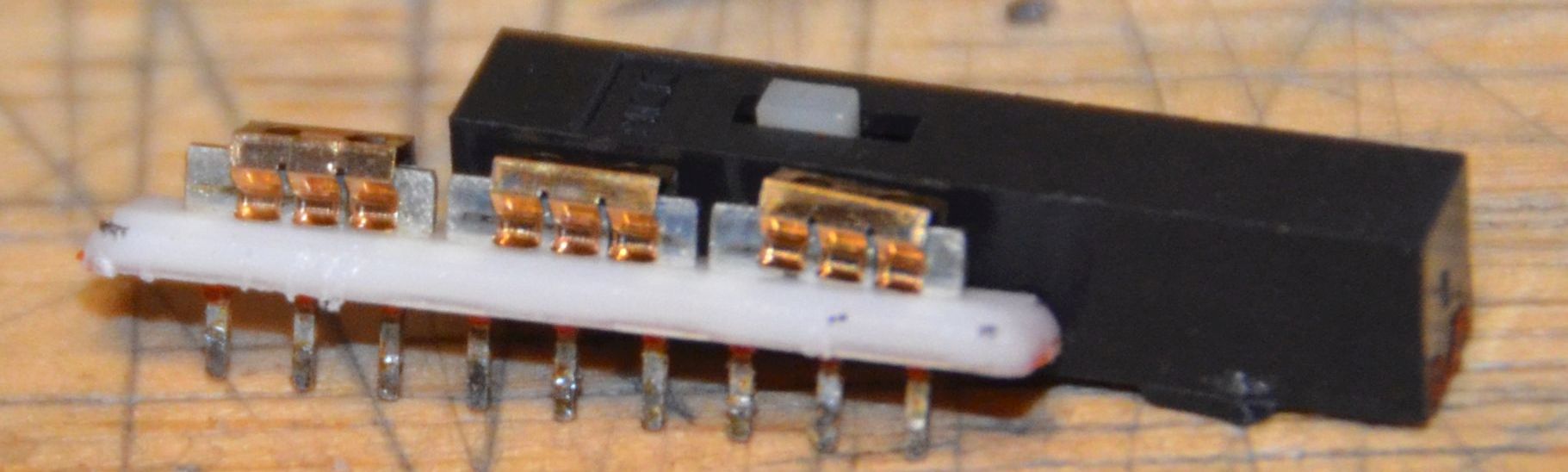

I had a 3.5" belt that fit for the small one, but you can see in the pic that it's sort of fat.The lower deck has four belts! I am still in the process of tearing it down carefully. Notes, notes, notes. The door must have its eject spring detached from the case inside before the deck will pull out. This is actually a really fun box to work on because every wire it attached to a removable connector.

Although that's nice, the function switch and volume knob need cleaning, and they're behind a ginormous tuner-preamp combo board which looks like the dial cord must come off to remove, so that's next.

Shining the flashlight through the back of the amp board looked kind of cool on the logo.

(Edit: I mis-spoke, the heat sink brackets to the lower deck for stability, so the rear screw only helps stabilize the upper deck.)

(Edit: I mis-spoke, the heat sink brackets to the lower deck for stability, so the rear screw only helps stabilize the upper deck.)

You are a righteous Dude.

You are a righteous Dude.