A couple of weeks ago I posted a thread entitled "Cabin Fever" (viewtopic.php?f=9&t=18527&hilit=cabin+fever), in which I basically re-built the deck on my M9990 out of sheer boredom. In addition to the standard cleaning and lube, I found that the take-up reel was slipping. This particular deck uses a clutch mechanism, rather than idlers, to engage the reels. The clutch lining material (some sort of felt) was perished from age.

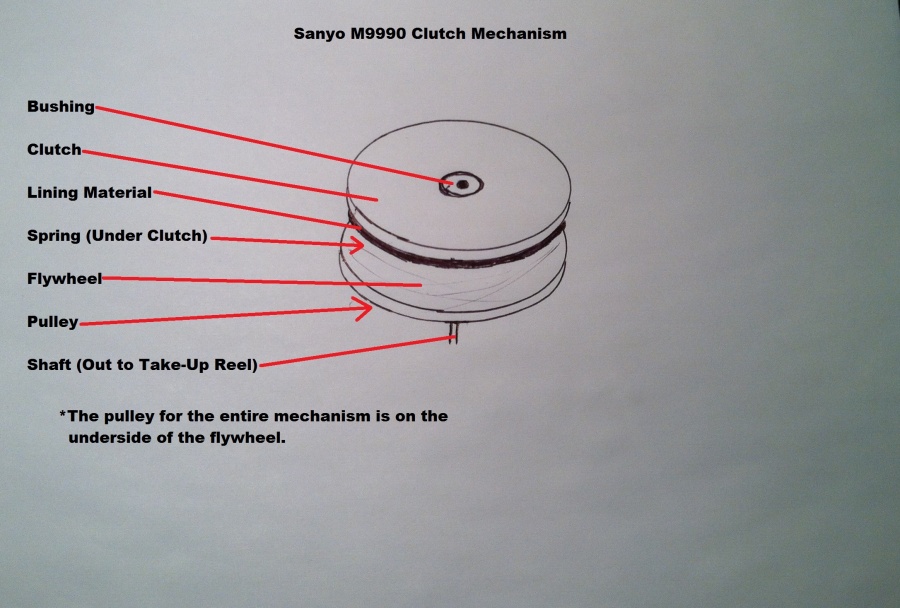

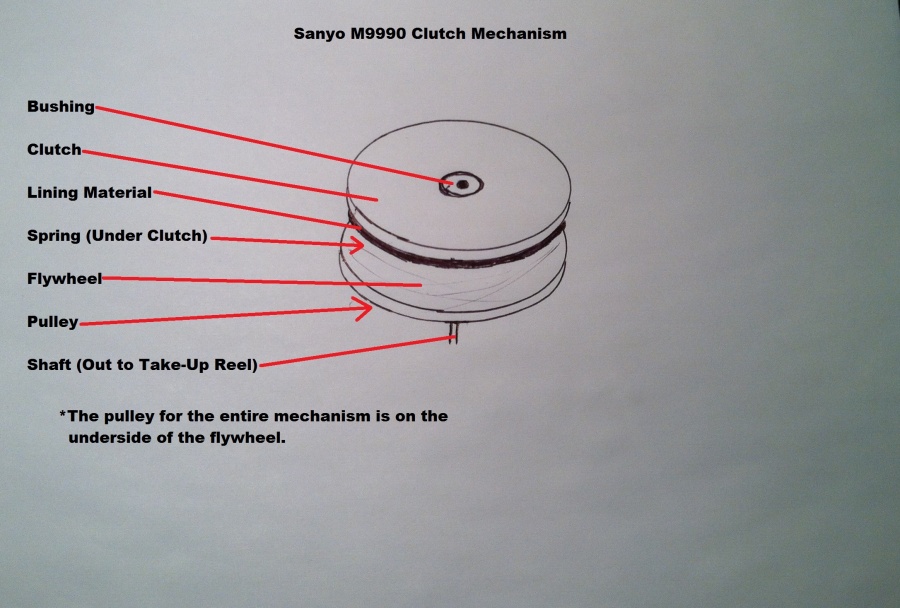

Here is a very rudimentary illustration I did to better explain how the mechanism is assembled.:

After removing the entire clutch assembly, the next step was to remove the clutch itself. It is all held together by a small bushing held in place by a tiny C-clip - and I mean this thing is tiny!

Next I peeled away the old lining material, which came off pretty easily.

In addition to my "day job," I also tune and repair pianos, so I always have parts and supplies on hand. So, off to the Parts Bin!

Pictured below is a scrap of piano action leather, which is used in escapement mechanisms, so it is the perfect candidate for a clutch liner- It GRIPS and SLIPS.:

Using the old lining material as a pattern, I made an exact duplicate out of the leather. I prepped the surface of the clutch by cleaning it with isopropyl, then a light sanding with 220 grit sandpaper for some bite. I then glued the new liner to the clutch with Aleene's Tacky Glue. BTW, in response to another Tech Talk thread, this stuff is great for re-foam jobs.:

After letting the glue set up for a couple of hours, I re-assembled the mechanism and re-installed it. The results speak for themselves (I posted a video on the Boomboxery Facebook page).:

I hope this thread helps out anyone with a slippy, sloppy Sanyo deck with this type of mechanism.

The deck was a little slow, but I found the small belt to be the culprit, so now she "purrs like a kitten."

Edit: The parts are really small, so work in a clean, organized area. It's a good idea to use a cloth or leather pad on your work surface to avoid rolling and bouncing parts. If that tiny C-clip goes flying, it's a gonner.

This deck is a real pleasure to work on, lemme tell ya (read aloud with heavy sarcasm).

It works great and should give years of service.

Here is a very rudimentary illustration I did to better explain how the mechanism is assembled.:

After removing the entire clutch assembly, the next step was to remove the clutch itself. It is all held together by a small bushing held in place by a tiny C-clip - and I mean this thing is tiny!

Next I peeled away the old lining material, which came off pretty easily.

In addition to my "day job," I also tune and repair pianos, so I always have parts and supplies on hand. So, off to the Parts Bin!

Pictured below is a scrap of piano action leather, which is used in escapement mechanisms, so it is the perfect candidate for a clutch liner- It GRIPS and SLIPS.:

Using the old lining material as a pattern, I made an exact duplicate out of the leather. I prepped the surface of the clutch by cleaning it with isopropyl, then a light sanding with 220 grit sandpaper for some bite. I then glued the new liner to the clutch with Aleene's Tacky Glue. BTW, in response to another Tech Talk thread, this stuff is great for re-foam jobs.:

After letting the glue set up for a couple of hours, I re-assembled the mechanism and re-installed it. The results speak for themselves (I posted a video on the Boomboxery Facebook page).:

I hope this thread helps out anyone with a slippy, sloppy Sanyo deck with this type of mechanism.

The deck was a little slow, but I found the small belt to be the culprit, so now she "purrs like a kitten."

Edit: The parts are really small, so work in a clean, organized area. It's a good idea to use a cloth or leather pad on your work surface to avoid rolling and bouncing parts. If that tiny C-clip goes flying, it's a gonner.

This deck is a real pleasure to work on, lemme tell ya (read aloud with heavy sarcasm).

It works great and should give years of service.